-

Home

-

About TKL

-

Factory Tour

-

Products

-

Blog

-

Contact Us

CONTACT

Leave Your Message

CONTACT

Well Head Equipment plays a crucial role in the oil and gas industry. It is the primary interface between the wellbore and surface facilities. According to the International Energy Agency (IEA), the global oil demand is expected to reach 104 million barrels per day by 2026. This increase affects the demand for efficient Well Head Equipment.

John Smith, a respected expert in the field, states, "Well Head Equipment is vital for safety and efficiency in oil extraction." These systems manage pressure and control fluids during drilling and production. Problems with well head systems can result in costly downtime. In 2021, it was reported that maintenance failures in this domain could lead to losses of up to $500,000 per day.

Understanding the complexities of Well Head Equipment is essential. Industry professionals must navigate technical specifications and maintenance schedules. Equipment configurations may vary, requiring tailored solutions for each well. There are always challenges to address. For instance, some equipment may not function as intended, causing unnecessary delays. A greater focus on innovation is needed to improve reliability and performance.

Well head equipment plays a crucial role in oil and gas production. It is the surface termination of a well. This equipment manages the pressure, flow, and safety of the well. Without it, operations could be risky. The complexity of well head systems is often underestimated. Each component has a specific function. These parts include valves, connectors, and gauges.

Pressure control is one of the primary functions. Well head equipment keeps pressures within safe limits. If pressure rises too high, it could lead to blowouts. A well-designed system helps to prevent this. Additionally, accurate measurements from gauges ensure optimal performance. They allow operators to monitor conditions closely.

However, challenges exist. Equipment can fail due to wear or poor maintenance. Even minor issues can lead to major setbacks. Regular inspections are necessary but often overlooked. This reflects a need for improvement in maintenance protocols. Proper training for personnel is also vital. Understanding well head equipment is essential for safe operations.

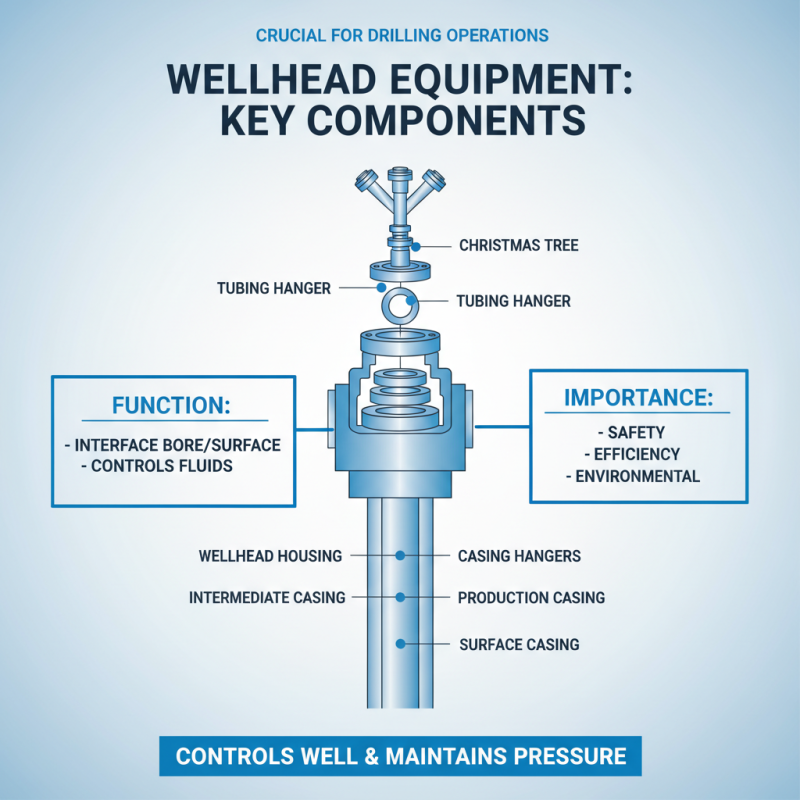

Understanding well head equipment is crucial for any drilling operation. The well head serves as the main interface between the wellbore and surface facilities. It controls the well and maintains pressure. There are several key components to consider.

The casing head is essential. It connects the surface casing to the wellhead. This component holds the casing in place and creates a seal to prevent leaks. A blowout preventer (BOP) is vital for safety. It can control unexpected surges in pressure. Operators must ensure it is always functional.

**Tips:** Regular maintenance is vital. Wear and tear can lead to problems. Check seals frequently. A small leak can cause significant hazards.

Another important part is the christmas tree. This manages the flow of oil, gas, or water. It typically includes valves and gauges. Properly setting the valves is crucial. Incorrect settings can lead to unwanted flow rates.

**Tips:** Training is necessary for all personnel. Accurate operation of these tools is critical. One mistake can result in disastrous consequences. Always double-check your work before proceeding.

Monitoring equipment is also important. Sensors can detect changes in pressure and temperature. Operators must pay attention to these readings. Anomalies should always raise concern and prompt action.

The safety of well head equipment is critical in the oil and gas industry. Industry standards and regulations ensure that equipment meets safety requirements to prevent accidents. According to the American Petroleum Institute (API), inadequate protection can result in severe environmental impacts and workplace hazards. Approximately 25% of all oil and gas incidents are linked to well head failures.

Regulatory bodies like the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) set guidelines to mitigate risks. They mandate regular inspections and maintenance of equipment. Non-compliance can lead to hefty fines and increased liability. Yet, many operators still struggle to adhere to safety protocols, risking both personnel and the environment.

The implementation of real-time monitoring systems is gaining traction. However, not all operators invest in advanced technologies. They often focus on immediate costs rather than long-term safety benefits. This oversight can lead to repeated incidents and costly legal battles. Safety is not just about compliance; it's about ongoing commitment to improvement and vigilance.

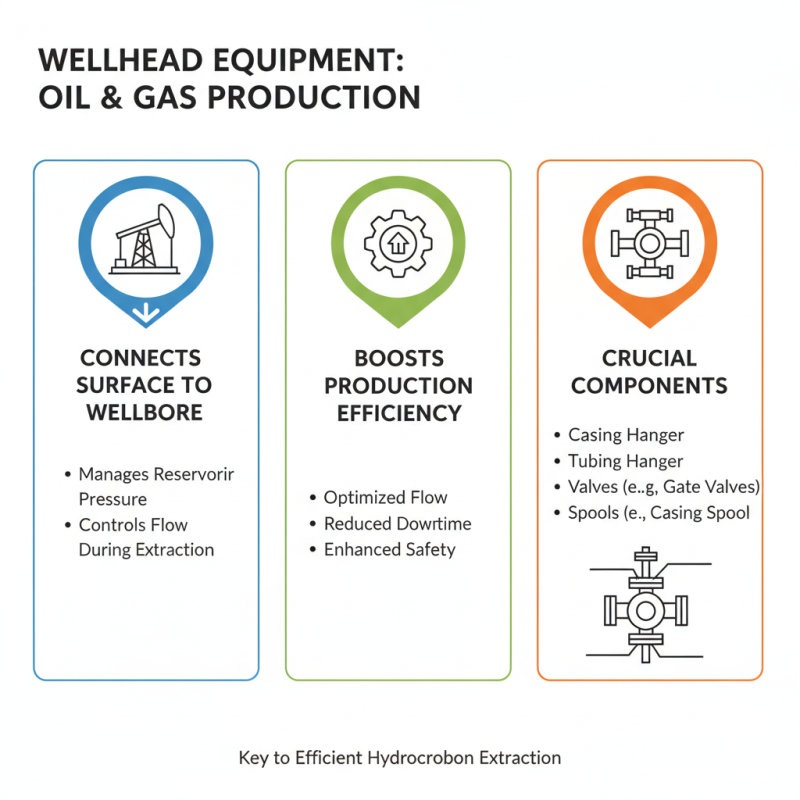

Wellhead equipment is crucial in oil and gas production. It connects the surface facility to the wellbore. This equipment greatly influences the efficiency of production. Properly designed wellhead components help manage reservoir pressure. They also play a vital role in flow control during extraction.

Maintaining wellhead integrity is essential. If the equipment fails, production can halt. Issues like leaks and blockages can arise. Operators must routinely check seals and valves. This reflects an ongoing commitment to safety and efficiency. However, many still overlook regular maintenance. The consequences can be severe. Thus, operators must stay vigilant to enhance performance.

Wellhead equipment also affects reservoir management. It can optimize recovery rates if managed well. For instance, adjusting pressure settings can maximize output. Yet, these adjustments carry risks. A poor decision can lead to reservoir damage. Operators need to weigh their options carefully. Balancing efficiency and safety is not straightforward. It requires ongoing training and adaptation.

The future of well head technology is evolving rapidly. Recent industry reports show that investments in this sector are projected to increase by 15% annually. Innovations are focusing on automation and data analytics, which enhance safety and efficiency. Advanced sensors now monitor pressure and temperature in real time. This allows for earlier detection of potential failures.

Tips: Regular maintenance is crucial. Schedule checks to prevent unexpected breakdowns.

Additionally, materials used in well head construction are improving. Lightweight alloys and composites are gaining traction. They offer better resistance to corrosion and extreme temperatures. However, this shift may lead to more technical challenges during installation and operation. Training for engineers is essential to navigate these new complexities.

Tips: Stay updated with training workshops. Knowledge of new materials can prevent mishaps.

The integration of Artificial Intelligence is another exciting trend. AI can analyze data from multiple wells and provide insights. This capability helps operators optimize production rates significantly. Although promising, AI implementation needs careful consideration of data security and system compatibility. Balancing innovation with reliability requires ongoing evaluation and adaptation.

| Feature | Current Technology | Future Trends | Innovation Impacts |

|---|---|---|---|

| Pressure Control | Conventional valves and BOPs | Smart pressure control systems | Increased safety and efficiency |

| Material Technology | Steel and alloys | Composite and nanomaterials | Lighter, more durable equipment |

| Automation | Manual controls | Automated control systems | Reduced human error, improved monitoring |

| Monitoring Systems | Basic telemetry | Advanced AI analytics | Real-time decision-making |

| Safety Features | Standard safety measures | Predictive maintenance technologies | Reduction in accidents and downtime |