-

Home

-

About TKL

-

Factory Tour

-

Products

-

Blog

-

Contact Us

CONTACT

Leave Your Message

CONTACT

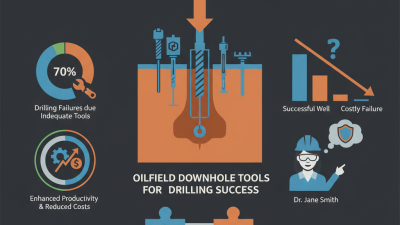

The oil and gas industry heavily relies on efficient drilling and production methods. According to John Doe, a leading expert in Oil Well Tools, "The right tools can significantly enhance productivity." This statement underscores the importance of selecting the best equipment for each job.

Companies are continually seeking innovative Oil Well Tools to optimize operations. Advanced drilling techniques have been developed, but challenges still exist. Equipment failures can halt production and lead to costly delays. It’s crucial to assess and upgrade tools regularly, ensuring reliability and efficiency in the field.

Moreover, the landscape of oil drilling is changing. Environmental concerns prompt new strategies and technologies. The tools must adapt to these requirements without compromising performance. Investing in high-quality Oil Well Tools is not just a trend; it's a necessity for sustainable production practices.

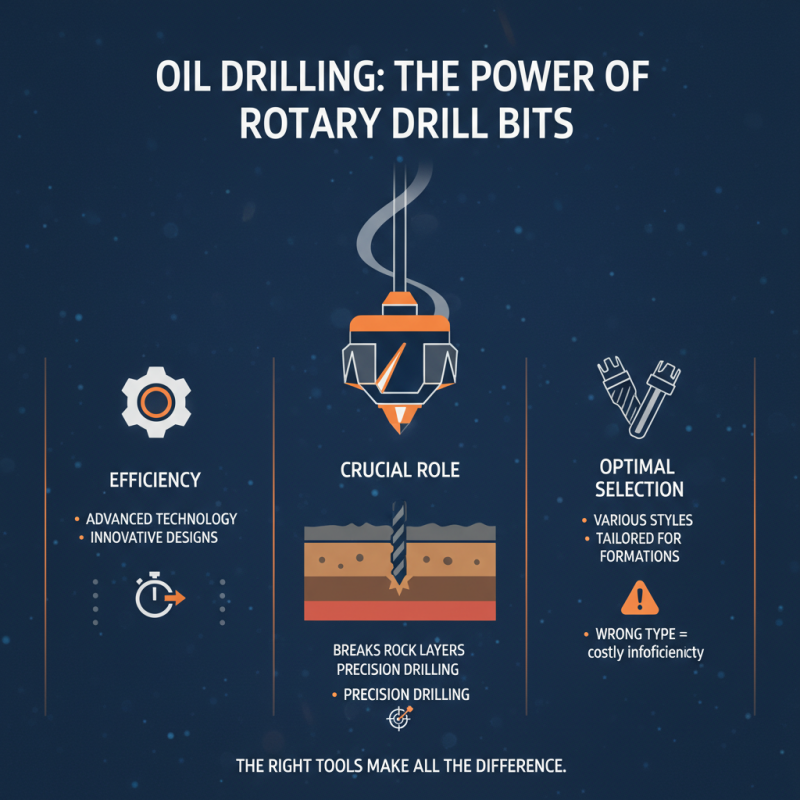

In the world of oil drilling, the right tools can make all the difference. Efficient drilling relies on advanced technology and innovative designs. Rotary drill bits play a crucial role, breaking rock layers with precision. These bits come in various styles, tailored for different formations. Using the wrong type can lead to inefficiency and increased costs.

Another essential tool is the mud pump. It circulates drilling fluid, cooling the bit and removing cuttings. However, not all mud pumps are created equal. Some may not handle high-viscosity fluids well. This can lead to delays and unscheduled maintenance.

Finally, casing and completion tools help secure the well and optimize production. Choosing the right casing design is vital. Poor choices can lead to leaks and environmental risks. Operators must constantly evaluate their methods for improvement. Each tool in the drilling process needs careful consideration and occasional re-evaluation to maximize efficiency in oil extraction.

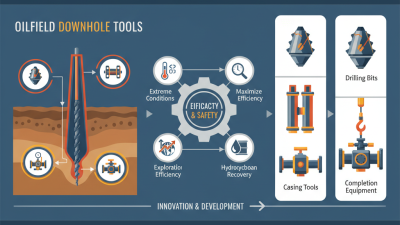

Drilling oil wells relies on a variety of tools designed to enhance efficiency and optimize production. One essential tool is the drill bit, which penetrates the earth’s surface. The choice of drill bit can impact performance significantly. According to industry reports, a robust design can increase drilling speed by over 30%. However, the selection of material must balance cost with durability, often leading to reconsiderations.

Another key tool is the mud pump, which circulates drilling fluid. This fluid cools the drill bit and carries rock cuttings to the surface. Reports indicate that proper mud properties can improve wellbore stability by up to 25%. Yet, maintaining optimal fluid characteristics poses challenges. Operators sometimes struggle with fluid loss or contamination, leading to delays and increased costs.

Casing systems, used for well integrity, also play a critical role. They provide support and prevent collapse during production. Studies suggest that using better materials can reduce failure rates significantly. Still, there are instances where improper installation leads to issues. This necessitates constant evaluation and innovation, pushing the industry to rethink existing practices.

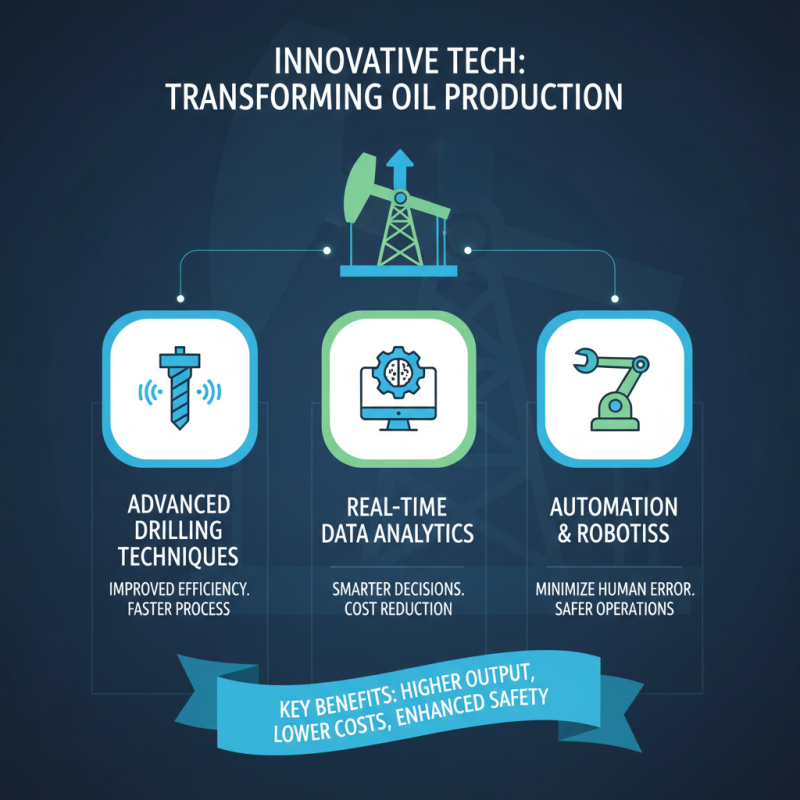

Innovative technologies are changing the landscape of oil well production. Advanced drilling techniques and better tools lead to improved efficiency. For instance, using real-time data can help drillers make smarter decisions. This speeds up the process and reduces costs. Automation also plays a vital role. It can minimize the risk of human error during drilling operations.

Tips: Stay updated on emerging technologies. Attending industry conferences can provide valuable insights. Also, consider training sessions to improve staff skills.

Implementing smart sensors in well sites enhances monitoring. These sensors detect leaks and pressure changes. If a problem arises, operators can react quickly. However, reliance on technology can also create challenges. Systems may fail unexpectedly, risking production disruption.

Tips: Regular maintenance of equipment is essential. Develop a contingency plan for tech failures. Training staff to handle unexpected situations can save time and resources.

Choosing the right oil well tools is crucial for success in drilling operations. It can significantly impact efficiency and production rates. Different drilling conditions require specific approaches. For soft formations, using a PDC bit can be effective, while harder rock formations might need a tricone bit. Each situation demands careful consideration.

When selecting tools, assess the formation type. For unstable formations, tools that minimize vibration can be beneficial. In contrast, high-pressure environments may require robust downhole equipment. It is not uncommon to encounter unexpected challenges. One must be prepared to adapt and rethink strategies on site.

Proper maintenance is also essential. Regular checks can prevent costly downtime. Sometimes tools wear out faster than expected. This can lead to inefficiencies and delays. In the field, it is common to learn from mishaps. Every project offers insights for future improvements. Adjusting tool selection based on past experiences can lead to better outcomes.

| Tool Type | Applications | Material | Benefits | Optimal Conditions |

|---|---|---|---|---|

| Drill Bits | Rotary drilling | Carbide, diamond | High durability, effective cutting | Hard rock formations |

| Top Drive Systems | Vertical and inclined drilling | Steel, aluminum | Increased drilling speed, improved torque | Deep well drilling |

| Mud Pumps | Circulating drilling fluid | Cast iron, stainless steel | Efficient fluid circulation, cooling | All drilling environments |

| Formation Evaluation Tools | Formation pressure and permeability assessment | Various metals and sensors | Accurate data acquisition | Variable formations |

| Casing and Production Tubing | Well casing and production | Steel, PVC | Structural integrity | Various well depths |

The oil industry is evolving rapidly. New tools are emerging, enhancing efficiency in drilling and production. According to a recent report by the International Energy Agency, improvements in drilling technologies could boost production rates by 20%. This means more oil can be extracted while reducing operational costs.

Digital technologies are reshaping drilling techniques. IoT and data analytics enable real-time monitoring, improving decision-making. Robotics and automation tools enhance accuracy and speed, leading to safer operations. These innovations significantly impact how drilling rigs operate, but not all companies adapt quickly. Some still rely on outdated methods, leading to inefficiencies.