-

Home

-

About TKL

-

Factory Tour

-

Products

-

Blog

-

Contact Us

CONTACT

Leave Your Message

CONTACT

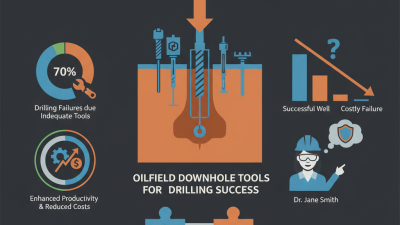

The oil and gas industry relies heavily on Oilfield Downhole Tools to enhance drilling efficiency. According to a 2023 report by the International Energy Agency, effective use of these tools can lead to a 30% reduction in operational costs. However, many operators still face challenges in optimizing their performance.

Properly selecting and maintaining these tools is essential. Poor choices often result in increased downtime and unexpected expenses. A study from the Society of Petroleum Engineers found that 40% of equipment failures are due to inadequate maintenance. This highlights the need for a proactive approach in the field.

Additionally, training personnel on the latest technologies can greatly improve outcomes. A significant investment in workforce education can yield higher productivity rates. Often, companies overlook this aspect, focusing instead on immediate results. Reflecting on these elements can pave the way for long-term success with Oilfield Downhole Tools.

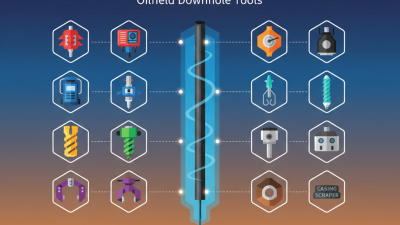

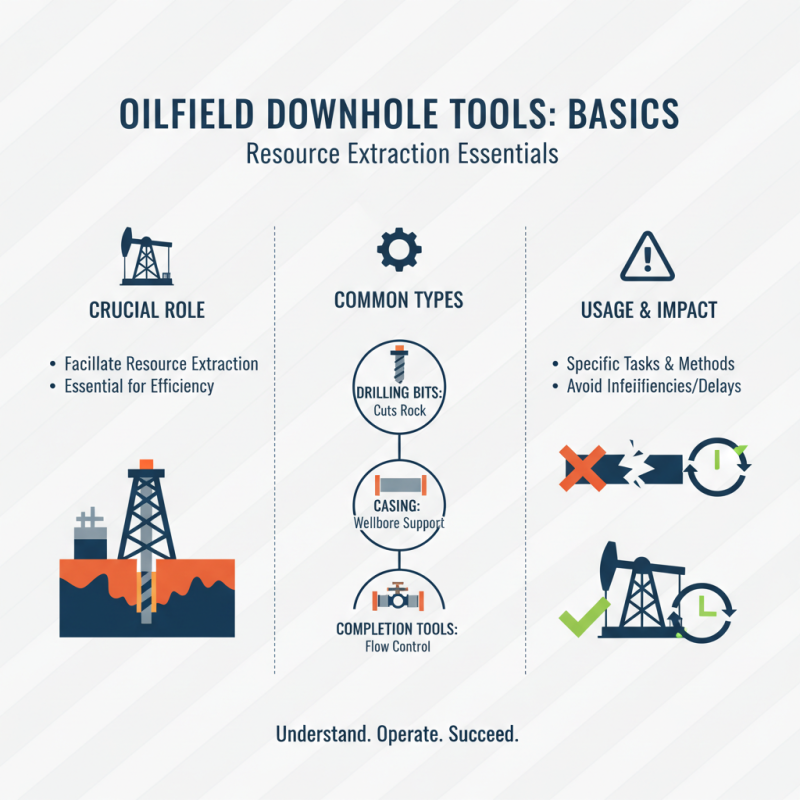

Oilfield downhole tools play a crucial role in the extraction of resources. Understanding their basics is essential for effective usage. These tools come in various forms, each designed for specific tasks. Common types include drilling bits, casing, and completion tools. Each tool has its own operational methods and specifications. Misunderstanding these can lead to inefficiencies or costly delays.

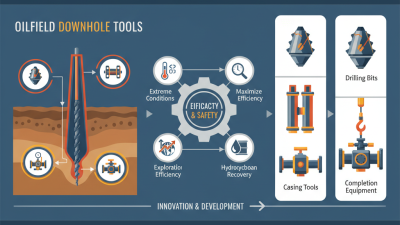

Safety is paramount while handling these tools. Workers must be aware of the potential hazards. Regular training and updates on tool advancements help maintain safety standards. Downtime can occur due to improper tool selection or lack of maintenance. Failing to address wear and tear on equipment can lead to accidents. A clear understanding of the operational limits of each tool is necessary for avoiding mishaps.

Knowledge of the geological environment is vital when selecting downhole tools. Different formations require different approaches. For example, hard rock might need a more robust drill bit. However, even experienced crews can make mistakes in selection. Reflecting on past experiences can improve future decisions. Identifying patterns in tool failures can enhance overall operational efficiency.

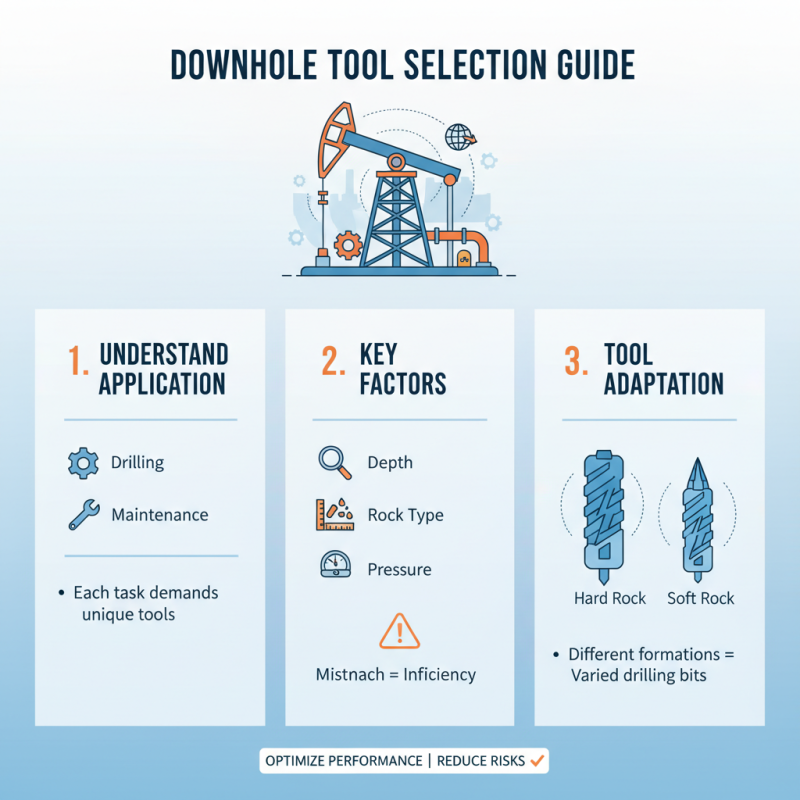

When selecting the right downhole tools, understanding your specific application is crucial. Each task, whether drilling or maintenance, demands unique tools. Consider factors like depth, rock type, and pressure. A tool that performs well in one environment may fail in another. For instance, different formations require varied drilling bits. A mismatch can lead to inefficiency.

Additionally, assess compatibility with existing equipment. Tools that fit well with other machinery can streamline operations. However, compatibility issues often arise, causing delays. Tools may also come with a learning curve. Staff should be trained adequately to avoid setbacks. Investing time in training is often overlooked but vital for successful tool usage.

Finally, always evaluate the feedback from operators. They can shed light on performance and usability. Their insights often reveal hidden issues or areas for improvement. Ignoring this feedback can lead to repeated mistakes. The right tools can enhance productivity significantly, but poor choices can hinder progress.

Maintaining and inspecting downhole tools is crucial for their effective use in oilfields. Regular inspections help identify wear or damage before they lead to bigger problems. Visible signs of wear, like scratches or dents, should not be ignored. These small issues can lead to costly failures.

One effective method is to create a checklist for inspections. This checklist can include components such as seals, joints, and connections. Each tool should be examined thoroughly. Sometimes, issues like stuck valves or excessive corrosion can go unnoticed. Ensure proper cleaning of tools after each use. This prevents residue buildup that can impair functionality.

Documentation of inspection results is essential. Keeping an accurate record allows for analyzing trends in tool performance. Reflect on past tool usage. Perhaps certain tools frequently fail in specific conditions. Learn from these experiences. It’s important to adapt and refine maintenance strategies over time. Continuous improvement is key to maximizing tool lifespan and effectiveness.

Optimizing the performance of downhole tools is crucial for efficiency in oilfield operations. Regular maintenance is key. Inspect tools for wear and tear. Schedule routine checks to avoid complications down the line. Small issues can lead to larger failures if neglected. Staying proactive prevents costly downtime and enhances tool reliability.

Selection of the right tools is vital. Not every tool fits every job. Understand the specific requirements of each project. Using inadequate tools can hinder performance and increase risks. Training the crew on tool usage is essential. A well-informed team can identify and correct potential misuse promptly, ensuring effective deployment in challenging conditions.

Common mistakes occur during the planning phase. Overlooking the environmental conditions can lead to issues. Each well presents unique challenges. Adapting strategies based on real-time data is critical. Feedback loops with the team can highlight inefficiencies and areas for improvement. Embrace these discussions; they can reveal blind spots and sharpen future approaches.

This bar chart illustrates the effectiveness score of the top 10 essential tips for optimizing the performance of downhole tools. Each tip is rated on a scale from 1 to 10, reflecting its importance in achieving better results in oilfield operations.

When operating downhole tools in oilfields, safety must always be a top priority. Workers should wear appropriate personal protective equipment, including hard hats, gloves, and steel-toed boots. This gear can prevent injuries from falling objects and sharp tools. Make sure to inspect all equipment before use. A small crack in a tool can lead to significant accidents.

Proper training is essential. Workers should understand how to operate tools safely. Even a minor mistake can have serious implications. Regular safety drills can help teams stay prepared for emergencies. Everyone should know the procedure for reporting incidents. It is vital to address any near-miss events and reflect on how they occurred.

Communication is crucial on-site. Establish clear signals for tool operation and movement. This step helps prevent accidents between workers and equipment. Too often, oversight happens in high-pressure situations. Teams must ensure that everyone is on the same page. Timing and coordination can save lives, but they require constant vigilance.

Safety in oilfields is not a one-time effort; it requires ongoing commitment and reflection.