-

Home

-

About TKL

-

Factory Tour

-

Products

-

Blog

-

Contact Us

CONTACT

Leave Your Message

CONTACT

In the ever-evolving world of drilling technology, Roller Reamers have emerged as a pivotal tool. Industry expert Dr. Alice Chen, a leading authority on drilling efficiency, once stated, "Effective use of Roller Reamers can enhance drilling performance significantly." This highlights the importance of understanding their application in various drilling scenarios.

Roller Reamers serve to widen the borehole while minimizing friction and wear. They provide a smoother drilling process, especially in challenging formations. However, many operators struggle to deploy these tools effectively. Misalignment can lead to decreased performance. This reality forces teams to reconsider their methods.

Adopting best practices is crucial. It's not just about the machinery; it's about the strategy. Success comes from understanding the nuances of Roller Reamers. A well-informed team can greatly reduce costly mistakes during drilling. Adjustments and learning from previous errors are essential for future success. Being open to change can ultimately lead to better results.

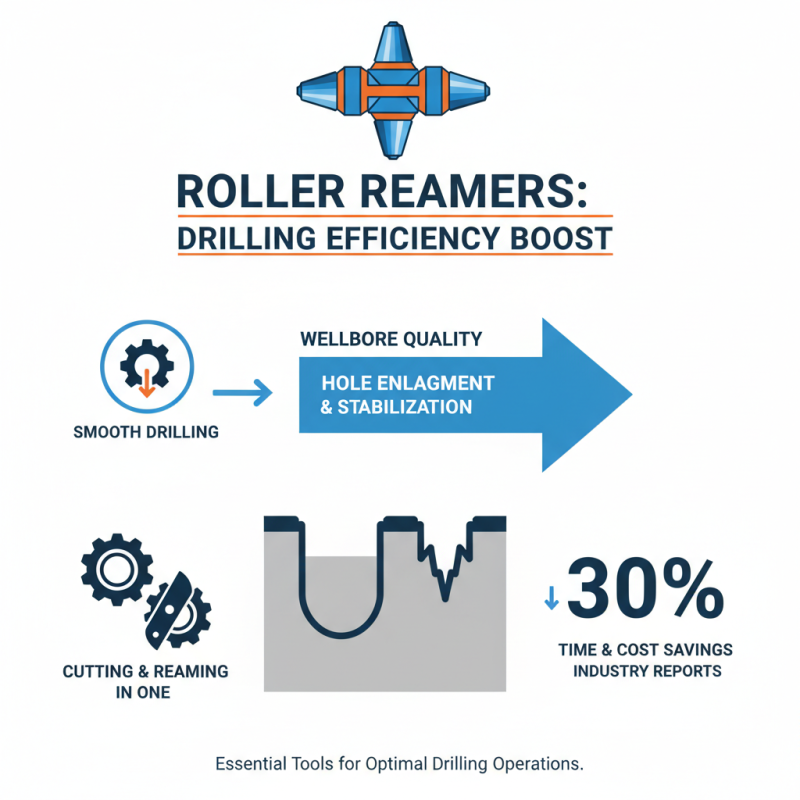

Roller reamers are crucial tools in the drilling industry. They enhance wellbore quality and ensure smooth drilling. These devices help to enlarge and stabilize holes. Their practical design allows for effective cutting and reaming in one operation. A well-executed drilling operation can lead to savings of up to 30% in time and costs, according to multiple industry reports.

When using roller reamers, consider the formation type. Different formations require different reamer designs. In hard rock formations, a robust roller reamer performs better. Conversely, softer formations may need fewer cutting elements. Adjusting the tool to the specific conditions is vital. The wrong choice could lead to wear or even tool failure.

Tips: Always monitor the weight on bit closely. This helps in optimizing performance. Keep an eye on the rate of penetration (ROP). A sudden drop in ROP could signal issues with the reamer. Regular checks are essential for maintaining efficiency. Remember, perfecting the use of roller reamers takes time and practice. Don't hesitate to review past drilling data for better decision-making. Fine-tuning your approach may yield remarkable improvements in performance and cost-efficiency.

Roller reamers play a critical role in the oil and gas industry. Their design helps enlarge boreholes while maintaining well stability. These tools can reduce the time spent on drilling operations. Additionally, they enhance the overall efficiency of the process.

To maximize the use of roller reamers, proper selection is key. Pick the right size suited for your specific needs. Ensure they match the formation type you are drilling through. A mismatch can lead to unexpected challenges. It’s essential to review the drilling parameters and tool compatibility regularly.

Tip: Monitor the performance data. This can guide future operations and tool adjustments. Address any issues promptly to prevent costly delays. A proactive approach is common among successful drilling teams. Consider team training on roller reamer operations. Such initiatives can improve efficiency and safety across projects.

Choosing the right roller reamer can greatly impact your drilling project. Start by assessing your specific drilling conditions. Consider the type of formation you’ll encounter. Different materials can wear out a reamer quickly. Hard formations require robust designs, while softer formations may need something lighter.

Tips: Evaluate rock hardness to select the best reamer. Look at the size and type of your drill bit. This will help ensure compatibility. Don’t rush this process; a wrong selection can lead to increased costs and delays.

Next, think about the reamer's configuration. Some designs excel in high-angle wells but may struggle in vertical settings. Matching the reamer to your drilling angle is crucial. Analyze your drilling strategy in detail. Keep in mind that a perfect match isn’t always available. Sometimes trade-offs are necessary.

Tips: Test various configurations in a controlled environment. Gather data on performance before full deployment. Keep communication open with your team to reflect on each choice’s outcomes. Adjust based on real-time feedback during drilling. This iterative process is key to success.

Operating roller reamers effectively requires careful planning. Start by ensuring you select the right type for your drilling needs. Understanding your well conditions is crucial. This knowledge can impact the performance of the reamer.

Once you've chosen your roller reamer, pay attention to the drill string. Check for any issues before starting. Proper maintenance of the tools is key. A clean and well-maintained reamer works better. Remember to monitor the drilling parameters closely. Adjust them as needed based on the feedback from the reamer.

Tips: Always keep your work area organized. It helps in reducing delays. Regular communication with your team is essential. Discuss any challenges you face. Don't hesitate to experiment with different operating techniques. Learning from mistakes can lead to better results. Embrace the lessons of each drilling session. Achievements can be built on reflection and improvement.

Using roller reamers can enhance drilling efficiency, but challenges often arise. One common issue is tool wear. Roller reamers may wear unevenly, leading to inconsistent hole sizes. Operators should regularly inspect tools for signs of wear. Adjusting the drilling parameters can help mitigate this problem. Slower drilling speeds may extend the life of the reamer.

Another challenge is the buildup of cuttings around the reamer. This can lead to jamming and inefficient drilling. Implementing a proper cleaning system can help. Regularly circulating drilling fluid flushes out debris. Be mindful of fluid viscosity and flow rates. They can significantly impact reamer performance.

Maintaining proper communication among the drilling team is essential. Misalignment in understanding can lead to mistakes. Operators must share insights and observations. Addressing issues together fosters a more efficient workflow. Recognizing these challenges is just the beginning. Continuous improvement and adaptability are key to successful drilling with roller reamers.

This chart showcases common challenges faced when using roller reamers in drilling operations, along with their corresponding frequency of occurrence and potential solutions.