-

Home

-

About TKL

-

Factory Tour

-

Products

-

Blog

-

Contact Us

CONTACT

Leave Your Message

CONTACT

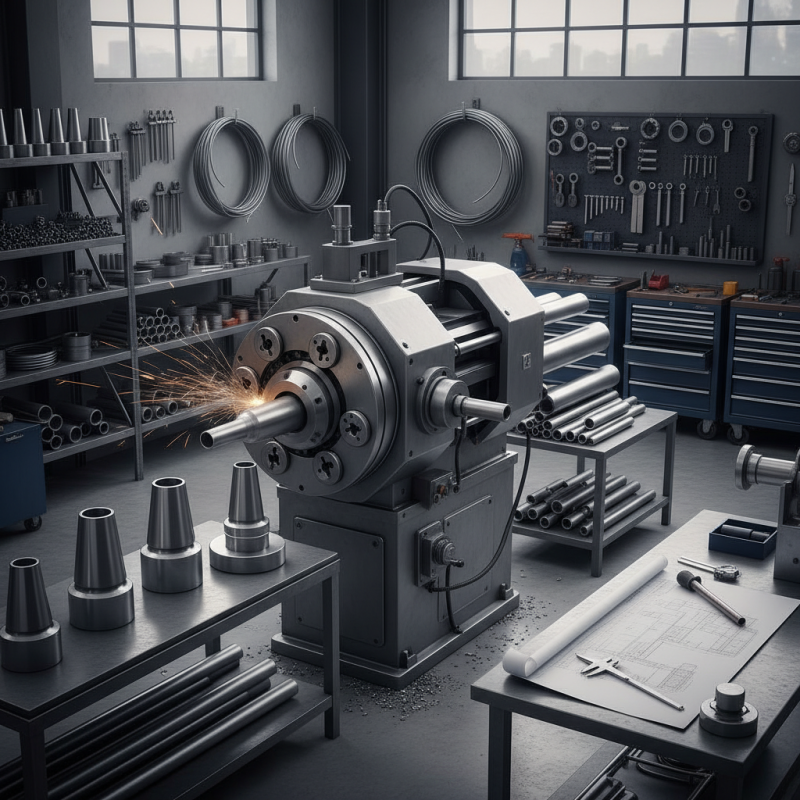

In recent years, the demand for efficient and reliable workshop equipment has surged. Among these, the Pipe Swaging Machine stands out as a vital tool for metalworking. Crafting pipes with precision and durability often hinges on the right swaging machine. It plays a crucial role in various applications, from HVAC systems to plumbing installations.

Choosing the best Pipe Swaging Machine for your workshop may seem daunting. Many options flood the market, each claiming to offer superior performance. It's essential to understand your specific needs and usage scenarios. The right machine should not only fit your budget but also deliver the desired results. Remember, investing in quality equipment pays off in the long run, reducing operational issues.

Some machines may pose challenges or require frequent adjustments. Assessing user reviews can provide insight into reliability and performance. Reflecting on your past experiences with different equipment can sharpen your decision-making process. Ultimately, selecting the right Pipe Swaging Machine will boost your productivity and enhance the quality of your work.

When considering pipe swaging machines for workshops, efficiency is crucial. These machines help shape and resize pipes with precision. Different models offer various features suitable for unique workshop needs. A well-chosen machine can streamline operations and enhance productivity.

Selecting the right machine requires careful evaluation. Size, capacity, and weight are essential factors. Many users overlook the importance of these details. An oversized machine could dominate space, becoming impractical. Conversely, a too-small model might not handle heavier tasks effectively. Finding the balance can be challenging.

Moreover, not all machines are user-friendly. Some may have complex controls that intimidate new users. Understanding the learning curve is important. Training staff might take extra time and resources. Workshops should be prepared for this potential hurdle. A machine that fits seamlessly into operations is vital for success and morale.

When selecting a pipe swaging machine, several key features matter significantly. One of the most important aspects is the machine's capacity to process various pipe sizes. A flexible machine accommodates both small and large diameters, making it suitable for diverse projects. However, not all machines excel in this area. Some may perform well with standard sizes but struggle with specialty pipes.

Another crucial factor is the ease of use. Operators should find the machine intuitive. Complicated controls or confusing setups can lead to mistakes. This may waste material and time, causing frustration. A machine with clear instructions and user-friendly controls is essential. Yet, many machines fall short on this front.

Lastly, consider energy efficiency. Machines that consume less power can save money in the long run. Still, priorities may vary among users. Some may prioritize power over efficiency. It's vital to balance these aspects based on specific needs. Evaluating all these features will ensure you make the right decision for your workshop.

When considering the best pipe swaging machine options in 2026, it's essential to focus on functionality and reliability. Numerous brands offer machines designed to make swaging a breeze. Many models are compact, making them suitable for workshops with limited space. Others boast a range of features, ensuring versatility for various tasks.

Some machines stand out due to their ease of use. Operators appreciate user-friendly controls and clear displays. Compact models often forgo some features, raising the question: are simpler machines sufficient for your needs? It's worth pondering whether a basic model may limit your workshop's potential.

Many recommend features like adjustable speeds and multiple dies. These can enhance the swaging process. However, this versatility might introduce complexity. Operators might feel overwhelmed or confused. So, while selecting a machine, balance options with your comfort level. The best choice is a blend of quality, necessary features, and personal skill.

In the world of pipe swaging machines, the market offers a variety of options tailored to workshop needs. Data indicates that prices can vary significantly—from around $1,500 to over $5,000. This disparity often reflects differences in performance, features, and build quality. For instance, basic models may suffice for light-duty tasks but may struggle with heavy metals or larger diameters. Performance can range widely, with some machines capable of swaging pipes up to 2 inches in diameter easily, while others may limit you to smaller sizes.

Consumer reports suggest that while higher-priced machines often deliver better durability and precision, less expensive models can also perform adequately for basic applications. Many users report issues like inconsistent results and mechanical failures with cheaper options. Buyers should consider their specific needs: will they be working with stainless steel? What is the expected workload? Understanding these factors is crucial. Investing in the right swaging machine can prevent costly rework and wasted materials in the long run. Reliable performance is key in achieving quality results, but many machines do not live up to their promises.

| Model | Max Pipe Diameter (inches) | Power (HP) | Weight (lbs) | Price Range ($) | User Rating (out of 5) |

|---|---|---|---|---|---|

| Model A | 1.5 | 2 | 150 | 400-500 | 4.5 |

| Model B | 2.0 | 3 | 180 | 600-700 | 4.0 |

| Model C | 2.5 | 3.5 | 200 | 700-800 | 4.7 |

| Model D | 3.0 | 5 | 250 | 900-1000 | 4.8 |

| Model E | 3.5 | 7 | 300 | 1200-1300 | 4.9 |

Maintaining your pipe swaging machine is crucial for optimal performance. Regular cleaning is essential. Dust and debris can interfere with operations. Use a soft brush to remove particles. Wipe the surfaces with a cloth to keep them clean. It's a small task, but it makes a big difference.

Check the hydraulic fluid levels frequently. Low fluid can decrease power. Replace any worn hoses or seals. Ignoring these issues can lead to costly repairs. Additionally, always inspect the machine for signs of wear. Watch for unusual noises during operation. These can signal potential problems, requiring immediate attention.

Lubrication is another key aspect. Grease moving parts regularly. This prevents metal fatigue and increases the machine's lifespan. However, over-lubrication is a real risk. Excess grease can attract dirt. It’s a balance that needs to be managed. Track maintenance schedules. Keeping a record ensures you don't overlook important checks. In the end, consistency in maintenance pays off in extended use.