-

Home

-

About TKL

-

Factory Tour

-

Products

-

Blog

-

Contact Us

CONTACT

Leave Your Message

CONTACT

In the ever-evolving world of drilling, the pursuit of efficiency and innovation is paramount. Dr. Emily Parker, a leading expert in Drilling Equipment, once stated, “Innovation is not just a choice; it’s a necessity for success.” This sentiment rings true as we look toward 2026, where advancements promise to redefine the industry.

The best drilling equipment will play a critical role in enhancing productivity. Today’s market presents a plethora of options, from cutting-edge drill bits to automated systems. Each piece of equipment must work seamlessly to ensure optimal performance under various conditions. However, it’s essential to acknowledge that not every tool is perfect. Some may fall short of expectations, leading to frustrations and inefficiencies.

As we anticipate future developments, we must also reflect on our current practices. While innovation drives us forward, challenges remain. Identifying the best drilling equipment requires a thorough understanding of the job at hand. This journey toward improvement is ongoing, demanding both introspection and a willingness to adapt. In this landscape, staying informed about the latest trends and technologies is crucial for any drilling operation aiming for excellence.

As we approach 2026, the drilling equipment industry is poised for significant advancements. Enhanced automation technologies are driving efficiency. Smart sensors and AI integration allow for real-time data analysis, leading to smarter decisions during drilling operations. With fewer human errors, these innovations increase safety and productivity.

Sustainable practices are crucial for the sector's future. Many companies are exploring eco-friendly materials and methods. Drilling techniques that minimize environmental impact are being prioritized. However, implementing these practices can be a challenge. The transition requires substantial investment and a willingness to rethink traditional processes.

Additionally, user-friendly interfaces improve operational efficiency. Operators with less experience can manage complex equipment effectively. Yet, this reliance on technology can create gaps in foundational skills. Balancing innovation with skill development will be key. Maintaining a workforce adept at tackling both advanced tools and basic processes is essential for long-term success.

| Equipment Type | Key Features | Efficiency Rating | Innovation Metric | Emerging Trends |

|---|---|---|---|---|

| Rotary Drills | High Torque, Adjustable Speed | 85% | Advanced Automation | Smart Sensors Integration |

| Directional Drillers | GPS Tracking, Real-Time Monitoring | 90% | Data Analytics Capabilities | Climate Resilient Operations |

| Hydraulic Drills | Increased Force, Energy Efficient | 88% | Hydraulic Innovation | Zero Emission Technologies |

| Smart Drilling Systems | Automated Controls, AI Integration | 95% | Robotics in Drilling | Predictive Maintenance |

| Portable Drilling Rigs | Compact Design, Lightweight | 82% | Modular Technology | Adaptable to Various Sites |

The drilling industry is evolving rapidly. Innovations are making drilling more efficient in 2026. New technologies focus on automation and precision. This leads to reduced downtime and improved performance. Advanced sensors are now a game-changer. They monitor conditions in real time. This helps prevent equipment failures.

Tips: Regular maintenance is key. Inspect your equipment often. Small issues can become big problems if ignored. Use data analytics to improve operations. Understanding patterns can enhance decision-making.

Increased use of eco-friendly materials is another trend. Companies are looking for sustainable options. This shift may reduce environmental impact. However, some methods can be tricky to implement. It's essential to weigh the pros and cons. Training staff on new technologies is crucial. Resistance to change can hinder progress. A balanced approach is necessary for success.

In 2026, the drilling equipment industry is poised to experience significant evolution. Performance metrics will play a crucial role in defining efficiency. Equipment that boasts faster penetration rates and improved durability will be highly sought after. Innovations in automation and remote operation are expected to redefine how drilling sites function. These advancements will lead to decreased downtime and enhanced safety.

However, not all innovations will come easily. Some technology may lead to increased complexities that require more training. As teams adapt, the initial learning curve can hinder performance. Maintenance of new components may also become a challenge, demanding regular assessments. Striking a balance between innovation and operational simplicity will be key for success.

Sustainability will be another focus. The industry is under pressure to reduce its carbon footprint. This could mean investing in greener technologies. Yet, not all stakeholders may prioritize these shifts equally. As efficiency metrics evolve, aligning innovation with environmental responsibility remains a critical challenge. The coming years will test the industry's resilience in meeting diverse performance expectations.

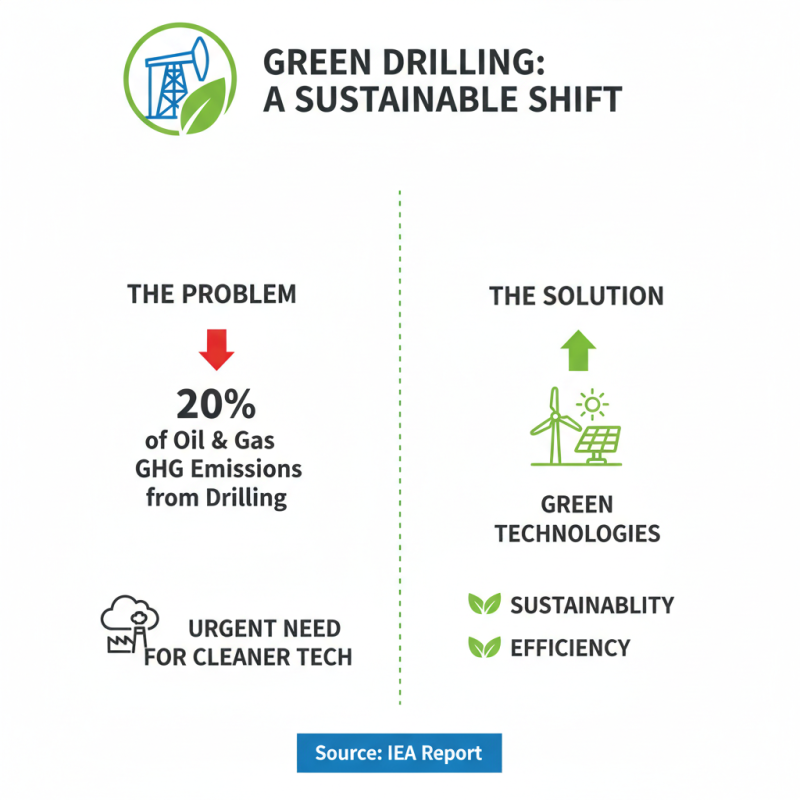

The drilling industry is experiencing a shift towards green technologies. These innovations focus on sustainability and efficiency. According to a recent report by the International Energy Agency, drilling activities account for about 20% of the total greenhouse gas emissions in oil and gas. This statistic highlights the urgent need for greener alternatives.

One promising development is the use of electric drilling rigs. These rigs reduce reliance on diesel fuel. A study found that electric rigs can cut emissions by up to 50%. This transformation is not only environmentally friendly but also cost-effective in the long term. However, challenges remain in the initial investment and infrastructure.

Additionally, advancements in precision drilling technology are noteworthy. This method allows for drilling with higher accuracy and less waste. Research indicates that improved precision can enhance resource extraction efficiency by over 30%. But, it requires skilled professionals and thorough training. The industry must confront these gaps to fully harness these innovations. The path towards greener drilling is complex, yet vital for sustainability.

The drilling equipment market in 2026 is evolving rapidly. New technologies are emerging, making it essential to understand the leaders in this sector. These companies are utilizing advanced materials and automation. Their tools are not only more efficient but also safer.

Many firms focus on innovation to improve performance. This trend emphasizes efficiency and reducing environmental impact. Some machines now utilize smart sensors, providing real-time data. Yet, there are challenges. Not every company can adapt quickly. Many struggle to keep up with rapid changes in technology.

The competition is fierce. Some companies invest heavily in research and development. This investment leads to new designs and better capabilities. However, not all innovations are practical or cost-effective. Finding the balance between cutting-edge features and affordability remains a challenge. As the market matures, the need for sustainable solutions grows. Companies must reflect on their methods to stay relevant.