-

Home

-

About TKL

-

Factory Tour

-

Products

-

Blog

-

Contact Us

CONTACT

Leave Your Message

CONTACT

The oil and gas industry relies heavily on efficient operations. Among the key components are Oilfield Downhole Tools. These tools play a vital role in optimizing production and minimizing costs. A recent report from the International Energy Agency states that effective tool usage can enhance drilling efficiency by up to 30%. This statistic highlights their importance in well performance.

Oilfield Downhole Tools are essential for various tasks. They include drilling bits, logging tools, and perforators. Each tool has unique functions that contribute to successful operations. For instance, advanced drilling bits reduce wear and improve penetration rates. Companies investing in these tools report higher return on investment. However, selecting the right tool can be challenging.

For starters, not all tools fit every situation. Some might even underperform in certain environments, leading to unexpected costs. It’s crucial to evaluate the specific conditions of each well. The wrong choice often results in delays and increased operational expenses. Understanding the features and benefits of each tool is key to making informed decisions.

Downhole tools play a crucial role in oilfield operations. Knowing the essential tools can improve efficiency. From drilling to completion, each tool has its specific purpose.

A mud motor is vital for directional drilling. It helps in steering the drill bit effectively. A packer is another essential tool used to isolate sections of the well. It helps maintain pressure in the wellbore. Casing centralizers ensure the casing is positioned correctly. This minimizes the risk of damage during cementing.

Tips: Always inspect tools before use. Ensure they are in good working condition. Routine maintenance can prevent unexpected failures. Consider the geology of the drilling site. Different formations may require specialized tools.

Remember, not every tool will work in every scenario. Sometimes, improvisation is necessary. This can lead to mistakes. Reflection on past experiences can foster growth. Learning from failures is just as important as celebrating successes.

Drill bits are crucial components in downhole applications. They are designed to cut through rock and soil efficiently. Various types of drill bits serve different purposes. Choosing the right one can be challenging but essential. Their design often includes hard materials like tungsten carbide. This ensures durability and effectiveness in various geological conditions.

The functionality of a drill bit largely depends on its features. For instance, some bits are meant for soft formations while others handle harder materials. PDC (Polycrystalline Diamond Compact) bits are known for their speed. They can penetrate tough surfaces quickly, but they may wear out faster in abrasive rocks. On the other hand, roller cone bits are versatile and suitable for a range of formations.

Consider the bit's size and shape for your project. A larger bit may drill faster but can create larger cuttings. Smaller bits might minimize formation damage but require more time. Sometimes, it’s challenging to predict the best type for specific conditions. Continuous monitoring in the field is critical for success. It’s a complex relationship between drilling method and geological features.

Logging tools play a crucial role in subsurface data acquisition. They help gather vital information about geological formations. This data is essential for effective decision-making in oilfield operations.

These tools include devices like acoustic, nuclear, and resistivity loggers. Each type provides unique insights into the subsurface. For instance, acoustic logging can reveal formation porosity and compaction. However, they also have limitations. The accuracy of measurements can be influenced by equipment conditions and environmental factors. Understanding these nuances is critical for successful data interpretation.

Challenges often arise in the field. For example, managing the data collected can be a daunting task. The volume of information can overwhelm teams, leading to potential oversights. Emphasis should be placed on training personnel to interpret this data correctly. A skilled operator can ensure that the insights gained are reliable, paving the way for better resource management.

| Tool Name | Function | Key Features | Applications |

|---|---|---|---|

| Logging Tool | Data Acquisition | Real-time data, high resolution | Formation evaluation, reservoir characterization |

| Mud Logger | Formation Evaluation | Real-time mud composition analysis | Drilling optimization |

| Wireline Tool | Data Retrieval | Depth control, data quality | Well logging |

| Formation Tester | Reservoir Testing | Pressure measurements | Fluid sampling |

| Directional Drilling Tool | Wellbore Positioning | High-precision alignment | Multi-directional drilling |

| Coiled Tubing Tool | Well Intervention | Continuous flexible tubing | Workover operations |

| Cementing Tool | Cement Placement | Controlled cement distribution | Well integrity |

| Reservoir Simulator | Modeling | Predictive analytics | Performance forecasting |

| Production Logging Tool | Production Measurement | Fluid flow measurement | Optimization of production |

| Wellbore Imaging Tool | Visual Analysis | High-resolution images | Geological assessment |

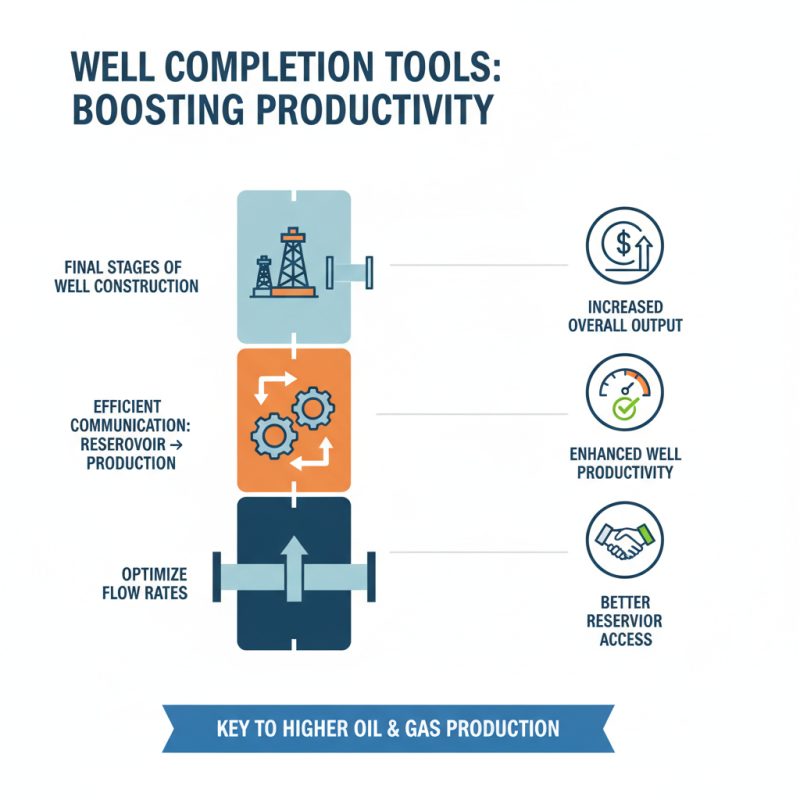

Completion tools play a crucial role in enhancing well productivity. These tools are used during the final stages of well construction. They help to establish efficient communication between the reservoir and production systems. By optimizing flow rates, they can significantly increase overall output.

Using various completion strategies can yield inconsistent results. Well design and reservoir characteristics often vary. Selecting the right combination of tools is essential. Each tool has unique capabilities. Some tools improve flow, while others mitigate challenges such as sand production or pressure changes.

Efficiency is not guaranteed. Operators must carefully analyze data and performance metrics. Misjudging the right insertion or retrieval method can lead to delays. Sometimes, simpler solutions may be overlooked. The objective should always be to maximize recovery while minimizing risks. Using advanced technologies can aid in decision-making. However, continuous evaluation is vital. Adapting to changing conditions remains a challenge for many teams.

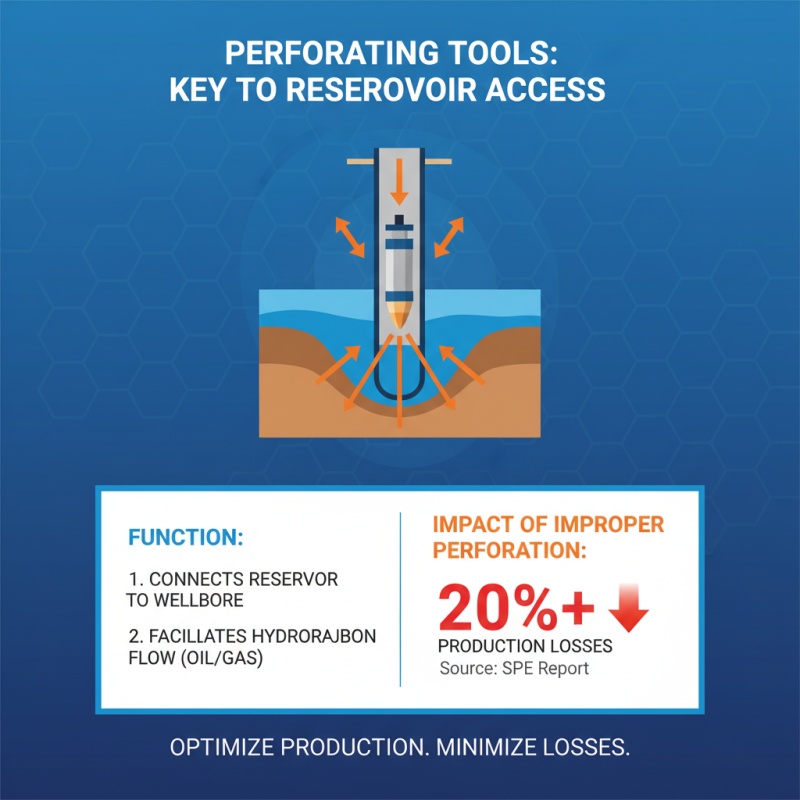

Perforating tools are critical for effective reservoir access. They facilitate the flow of hydrocarbons from the reservoir to the wellbore. According to a recent report by the Society of Petroleum Engineers, improper perforation can lead to significant production losses, sometimes exceeding 20%. This highlights their importance in the oilfield.

The design of perforating tools has evolved significantly over the years. Tools can now create more efficient pathways, maximizing reservoir permeability. However, challenges remain. Many operators underestimate the impact of formation characteristics on wireline perforation. Studies indicate that nearly 30% of operators do not adjust techniques based on specific geological data. This oversight can lead to incomplete reservoir access and lower production rates.

Data shows that well completion costs can skyrocket without the right perforating strategy. A recent analysis revealed that improper perforation often results in increased workover operations. This adds financial strain on already tight budgets. Operators must invest time analyzing formation properties. Failure to do so creates unnecessary risks. Understanding these nuances is crucial for enhancing production efficiency.