-

Home

-

About TKL

-

Factory Tour

-

Products

-

Blog

-

Contact Us

CONTACT

Leave Your Message

CONTACT

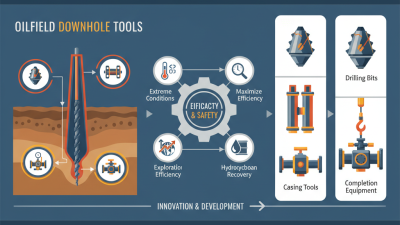

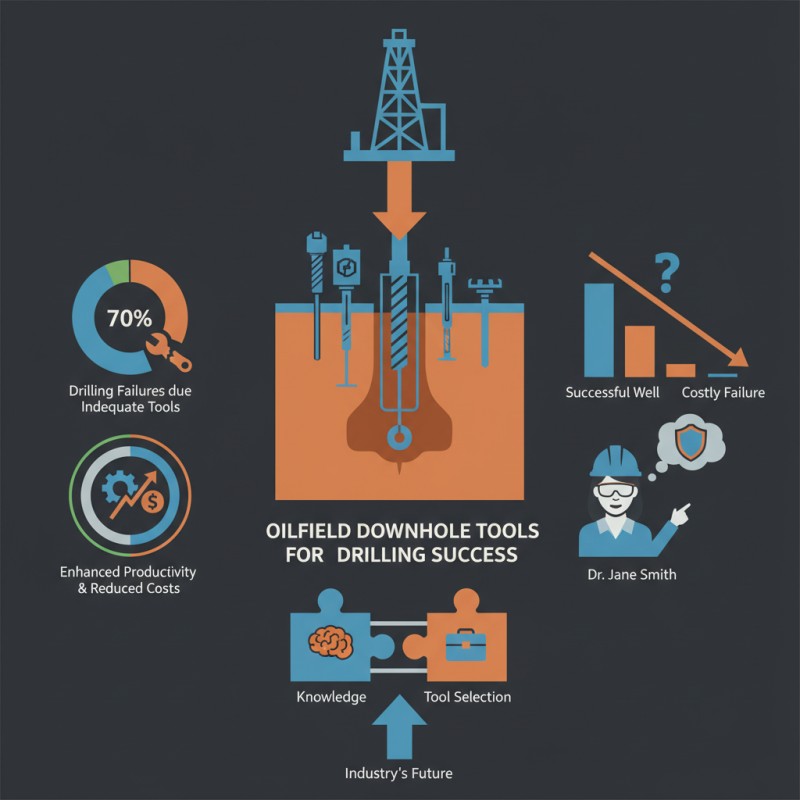

Oilfield Downhole Tools are critical for achieving drilling success. According to a report by the International Energy Agency, efficient drilling operations depend significantly on advanced downhole technology. These tools enhance productivity and reduce costs, directly impacting the overall success of oilfield projects.

Industry expert Dr. Jane Smith emphasizes the importance of these tools, stating, "Without reliable Oilfield Downhole Tools, drilling operations face higher risks and inefficiencies." In the field, the performance of these tools can determine the quality of extraction and safe operation. However, many operators still underestimate their significance, leading to increased operational issues and potential failures.

A recent survey revealed that 30% of drilling failures are related to inadequate downhole tool selection. This statistic highlights the need for companies to invest in high-quality, innovative equipment. Ultimately, the right Oilfield Downhole Tools can mean the difference between a successful well and a costly failure. Therefore, addressing gaps in knowledge and tool selection is essential for the industry's future.

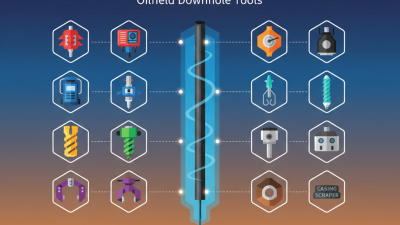

Downhole tools are critical for efficient oilfield drilling operations. They enable drilling teams to reach target depths effectively. These tools include drill bits, casing, and downhole sensors. Each component plays a unique role in the drilling process. The right tools can dramatically reduce drilling time and costs.

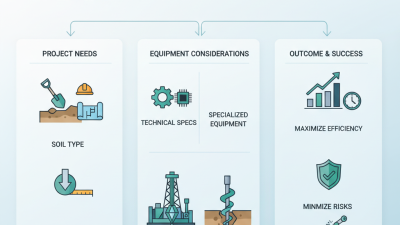

The performance of downhole tools can vary. Some tools may wear out faster than expected. This can lead to unexpected downtime. Regular inspections and maintenance are essential for optimal performance. The geological conditions greatly influence tool selection and usage. Not all tools perform best in every environment. Evaluating them based on the specific drilling situation is vital.

Flaws in tool design or material can cause issues. Teams must be prepared for these challenges. Proper training and knowledge help mitigate risks. A focus on innovation can lead to improvements. However, reliance on newer technologies carries its own risks. It’s crucial to balance innovation with proven methods. The effectiveness of downhole tools often shapes the overall success of drilling projects.

Downhole tools play a crucial role in drilling operations. They directly influence efficiency and success rates. Various tools are designed for specific tasks, ensuring optimal performance. For instance, drill bits are vital for penetrating the earth's crust. According to the International Association of Drilling Contractors, more than 30% of drilling failures relate to inappropriate bit selection.

Another important type of downhole tool is the drilling motor. These devices provide the necessary power to rotate the drill bit effectively. The right motor can enhance drilling speed by up to 50%. This increase can lead to considerable cost savings. However, improper selection or maintenance can result in catastrophic failures.

Measurement while drilling (MWD) tools allow real-time data collection. They improve decision-making on the fly. However, those tools require skilled operators for accurate data interpretation. Misreading data can lead to costly errors. It's clear that while downhole tools are indispensable, their effectiveness relies heavily on proper selection and operation.

Downhole tools play a crucial role in the efficiency and effectiveness of drilling operations. This chart compares various types of downhole tools based on their specific functions and usage in the drilling process.

Downhole tools are vital for successful drilling operations. Recent technological advancements have transformed their design and functionality. According to a report by the International Association of Drilling Contractors (IADC), advanced materials and electronic components contribute to enhanced performance and reliability. Modern downhole tools now feature improved resistance to extreme temperatures and pressures.

Innovative designs, like rotary steerable systems, allow for precise wellbore placement. This precision can increase drilling efficiency by up to 30%. However, the complexity of these tools raises challenges. Maintenance and replacement costs can be significant. Companies must balance advancements with financial constraints. Effective training is also crucial. Workers must understand new technologies to avoid costly errors.

The integration of sensors into downhole tools has further revolutionized drilling. Real-time data enhances decision-making abilities. Coupling this data with machine learning algorithms offers predictive analytics. But this technology can also create a dependency. Over-reliance on data might overlook fundamental skills. The drilling industry must navigate these advancements carefully while preserving traditional expertise.

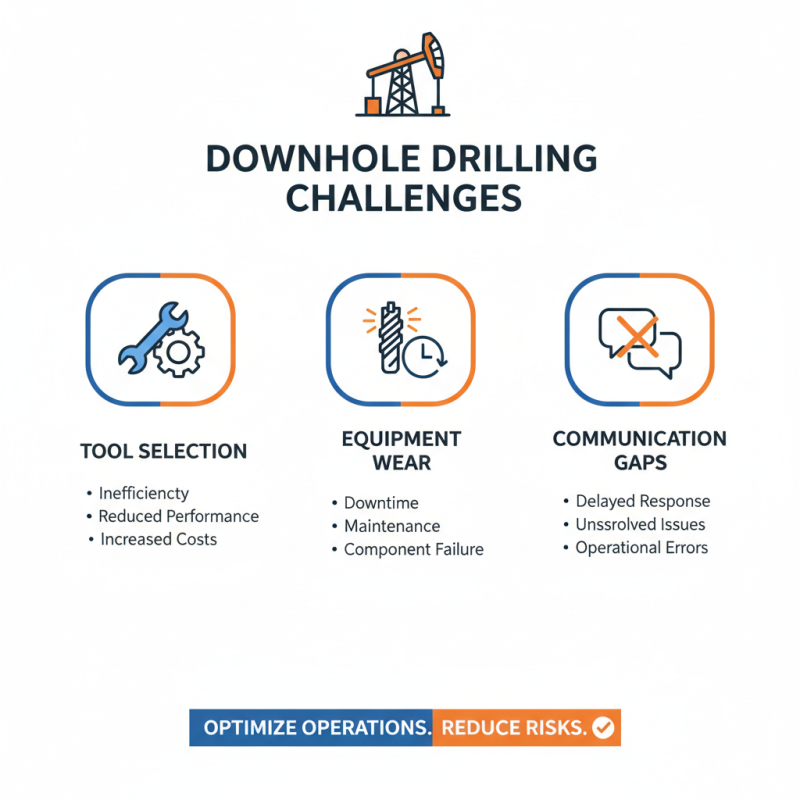

Downhole tools are crucial for drilling operations. They face various challenges that can hinder performance. For instance, improper tool selection can lead to inefficiencies. Operators may struggle with wear and tear on equipment. This can result in costly downtime. Sometimes, the communication between teams is weak. This can cause delays in addressing issues as they arise.

Choosing the right tools requires careful consideration. Geological conditions vary greatly and impact tool performance. Many operators underestimate the importance of testing. Misjudgments in tool capabilities can lead to project delays. Maintenance is another area that often gets overlooked. Regular inspections are necessary to prevent failures. A lack of proactive measures can result in further complications.

Training staff is essential for better downhole tool utilization. Knowledge gaps often lead to mistakes on-site. There’s a tendency to overlook new technologies as well. Embracing innovation is vital for success. Operators need to foster a culture of learning and adaptation. By doing so, they can better navigate the challenges of downhole tool usage.

Downhole tools play a critical role in drilling operations. Their design and function impact both efficiency and costs. Effective tools can reduce drilling time significantly. This translates to lower operational costs and better resource management.

Using high-quality downhole tools can prevent costly delays. A tool failure can lead to expensive repairs and extended downtime. Thus, regular maintenance is essential for these tools. Consider conducting thorough inspections before each drilling project. This practice helps in identifying potential issues early on.

Tip: Always invest in training for your crew. Knowledgeable personnel can operate tools more efficiently. Their expertise minimizes accidents and improves overall safety.

Remember, the drilling environment can be unpredictable. In some cases, even quality tools may not perform as expected. Continuous evaluation of drilling strategies is necessary. Refining operations based on real-world feedback can lead to improved performance over time.

| Tool Type | Function | Impact on Efficiency (10% Scale) | Cost Impact ($ per Foot) |

|---|---|---|---|

| Drill Bits | Cutting through rock and formations | 8 | $50 |

| Mud Motors | Rotating the drill bit using drilling fluid | 7 | $30 |

| Measurement While Drilling (MWD) | Providing real-time data on the drill's position and geology | 9 | $70 |

| Logging Tools | Recording geological and physical properties of formations | 6 | $40 |

| Casing Tools | Protecting the wellbore and preventing collapses | 5 | $35 |