-

Home

-

About TKL

-

Factory Tour

-

Products

-

Blog

-

Contact Us

CONTACT

Leave Your Message

CONTACT

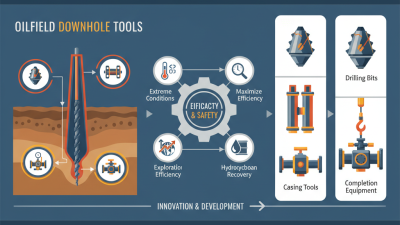

In the highly competitive world of oil drilling, the efficiency and success of operations heavily rely on the selection of appropriate technologies and tools. Among the key components of this technology arsenal are Oilfield Downhole Tools, which play a crucial role in optimizing the drilling process. These tools are designed to enhance the performance of drilling operations, minimize downtime, and ultimately reduce costs, making them indispensable for any oilfield operation.

As the demand for energy continues to rise, the need for advanced and reliable oilfield solutions becomes more pressing. The right combination of Oilfield Downhole Tools can significantly influence drilling outcomes, from wellbore stability to well completion. This article explores the top ten must-have tools that every oilfield operation should consider incorporating. By leveraging the latest innovations in downhole technology, operators can ensure enhanced productivity, improved safety, and a more sustainable approach to drilling activities. Whether you are a seasoned professional or new to the industry, understanding these essential tools is vital for achieving operational excellence in today’s oilfield landscape.

Efficient drilling operations hinge on the selection of essential downhole tools that enhance performance and minimize downtime. According to a report by the IADC, optimizing drilling efficiency can lead to a reduction in drilling costs by as much as 20-30%. This underscores the necessity of integrating high-quality downhole tools, which play critical roles throughout the drilling process. Tools such as drilling jars, memory systems, and rotary steerable systems are indispensable for drilling crews seeking to accelerate project timelines while maintaining safety standards.

One of the most impactful innovations in downhole technology is the deployment of advanced measurement-while-drilling (MWD) systems. A study conducted by the SPE indicates that the use of MWD can improve well placement accuracy by over 50%, thereby significantly increasing the chances of hitting target zones. Furthermore, the integration of intelligent drilling systems, which utilize real-time data analytics, has been shown to enhance operational response times, further driving efficiency. As the oil and gas industry continues to evolve, the reliance on cutting-edge downhole tools becomes not only a competitive advantage but a necessity for achieving operational excellence in today's challenging drilling environments.

Measurement While Drilling (MWD) technology has revolutionized the oil and gas drilling industry by providing real-time data that enhances operational efficiency. This technique involves using advanced sensors in the drill string to measure parameters such as temperature, pressure, and directional positioning while drilling. The immediate feedback enables drilling teams to make informed decisions, reducing the risk of costly errors and minimizing non-productive time. By incorporating MWD into drilling operations, companies can optimize wellbore placement, improve reservoir characterization, and achieve faster drilling cycles.

The implementation of MWD technology not only boosts the accuracy of drilling operations but also enhances safety. Traditional drilling methods often rely on post-drilling analysis, which can lead to delays and unforeseen complications. However, with MWD, operators can monitor drilling performance in real time, make necessary adjustments, and mitigate potential hazards as they arise. This proactive approach is essential in navigating challenging geological formations and maximizing resource extraction, ultimately contributing to a more efficient and sustainable energy operation.

In modern drilling operations, the role of rotary steerable systems (RSS) has become increasingly vital. Unlike conventional drilling methods that rely heavily on the rig crew to manually adjust the drill path, RSS enables real-time adjustments to the drill bit’s trajectory without the need to stop drilling. This technology allows for more precise control over the wellbore's inclination and azimuth, ultimately enhancing the efficiency of the drilling process. By facilitating smoother directional changes, RSS minimizes the risk of wellbore instability and reduces the overall time spent in the drilling phase.

The incorporation of rotary steerable systems also contributes to significant cost savings and improved resource management. With the ability to drill longer sections in a single run, operators can optimize their time and reduce the number of trips needed for bit changes. Furthermore, RSS reduces the wear and tear on drilling equipment, as continuous drilling lessens the likelihood of equipment failure or damage. As the demand for efficient energy extraction rises, the importance of adopting advanced technologies like rotary steerable systems cannot be overstated, shaping the future of drilling operations in a more effective and sustainable manner.

When evaluating downhole motors for increased speed in drilling operations, it is essential to consider several performance factors that directly impact efficiency. Downhole motors play a crucial role in transferring hydraulic energy into mechanical energy, allowing drill bits to penetrate rock formations effectively. Key parameters such as torque, RPM (revolutions per minute), and fluid efficiency can significantly influence the drilling speed and overall performance.

Tips: Always assess the compatibility of the downhole motor with your specific drilling environment. Different geological formations may require motors with unique features, such as adjustable settings or specialized designs that maximize performance under varying conditions. Conducting thorough tests in real-world settings can provide insights into which motor configurations yield the best results.

Additionally, maintenance plays a vital role in keeping downhole motors performing at their best. Regular inspections and preventative measures can help mitigate potential issues before they affect drilling operations. Ensuring that seals, bearings, and power section components are in optimal condition will not only enhance speed but also prolong the lifespan of the motor. Monitoring performance data consistently allows for timely adjustments that can boost operational efficiency.

| Tool Name | Type | Speed (RPM) | Torque (Nm) | Max Depth (m) | Weight (kg) |

|---|---|---|---|---|---|

| Downhole Motor A | Rotary | 200 | 300 | 4000 | 150 |

| Downhole Motor B | Rotary | 250 | 350 | 5000 | 160 |

| Downhole Tool C | PDC Bit | 300 | 400 | 4500 | 120 |

| Downhole Tool D | Mud Motor | 180 | 250 | 3500 | 140 |

| Downhole Tool E | Underreamer | 220 | 320 | 6000 | 170 |

| Downhole Tool F | Reamer | 210 | 310 | 5000 | 155 |

| Downhole Tool G | Stabilizer | 240 | 300 | 4000 | 145 |

| Downhole Tool H | Section Mill | 190 | 280 | 3500 | 130 |

| Downhole Tool I | Jet Nozzle | 230 | 350 | 4200 | 125 |

| Downhole Tool J | Whipstock | 160 | 270 | 3000 | 135 |

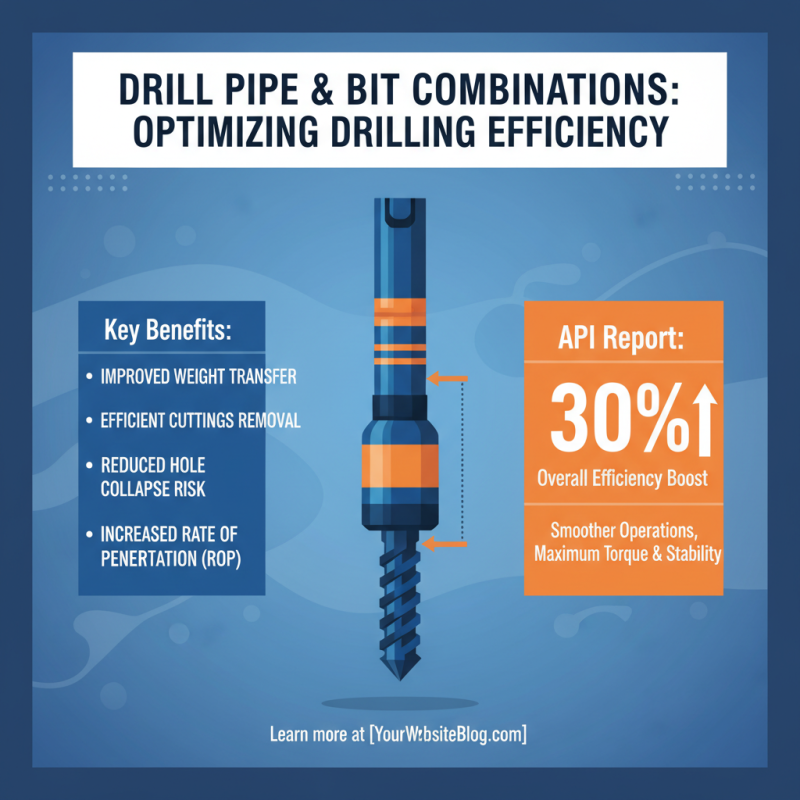

The combination of drill pipe and bit is a critical aspect of efficient drilling operations, significantly impacting the effectiveness of cuttings management. According to a report by the American Petroleum Institute (API), optimizing these combinations can improve overall drilling efficiency by as much as 30%. This enhancement is largely due to better weight transfer to the bit and efficient removal of cuttings, which minimizes the likelihood of hole collapse and increases the rate of penetration (ROP). By carefully selecting the right drill pipe and bit pairing, operators can ensure maximum torque and stability, leading to smoother drilling experiences.

Additionally, the synergy between drill pipe and bit design can influence the thermal dynamics within the wellbore. A study published in the Journal of Petroleum Technology found that an optimized drill bit can reduce heat generation by nearly 20%, which is crucial for prolonging both the bit's lifespan and the overall durability of the drilling assembly. These improvements not only reduce maintenance costs but also contribute to more sustainable drilling practices by lowering the frequency of tool replacement. Investing in a well-engineered combination of drill pipes and bits ultimately leads to enhanced operational efficiency, giving drilling operations a competitive advantage in increasingly challenging environments.

In the realm of drilling operations, the selection of effective Oilfield Downhole Tools is paramount for achieving optimal efficiency and performance. The article highlights the top ten essential downhole tools, which are crucial for enhancing drilling efficiency. Among these, Measurement While Drilling (MWD) technology plays a significant role by providing real-time data, enabling better decision-making during operations.

Furthermore, Rotary Steerable Systems are emphasized for their ability to improve directional drilling accuracy, while downhole motors are evaluated for their capacity to increase the speed of drilling. The article also discusses the advantages of pairing drill pipes with appropriate bits to optimize cuttings, thereby enhancing overall drilling outcomes. Lastly, a cost-benefit analysis underscores the value of investing in high-performance downhole tools, ultimately contributing to more successful drilling operations and a better return on investment.