-

Home

-

About TKL

-

Factory Tour

-

Products

-

Blog

-

Contact Us

CONTACT

Leave Your Message

CONTACT

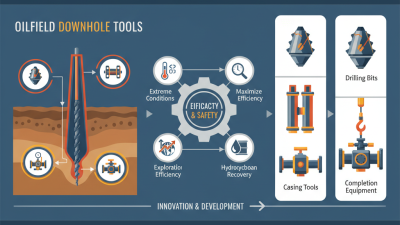

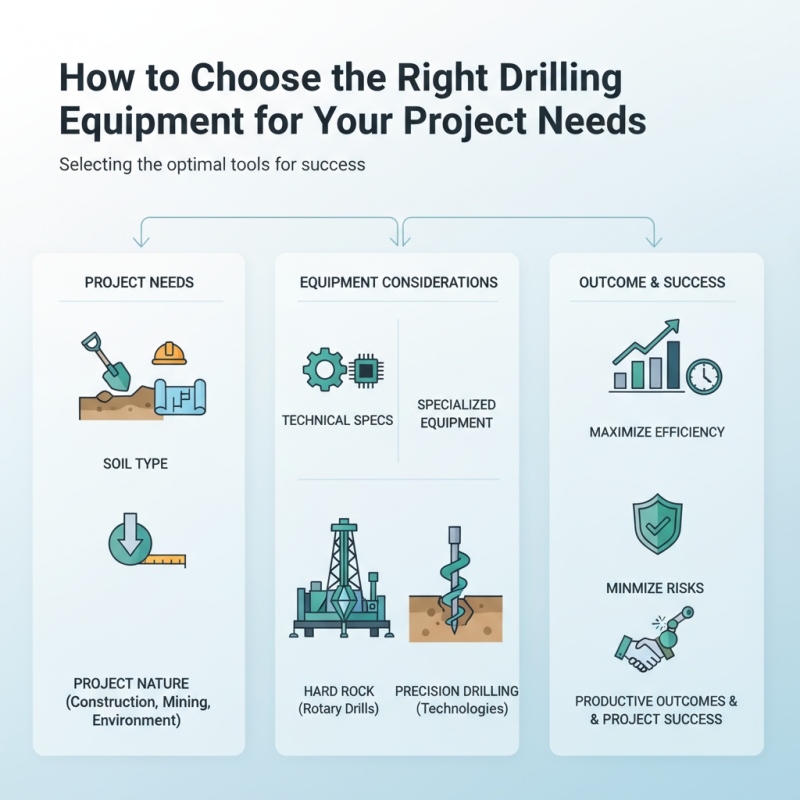

Selecting the right drilling equipment is crucial for the success of any drilling project, whether it involves construction, mining, or environmental exploration. The variety of available drilling equipment can be overwhelming, but understanding your specific project needs is the key to making an informed decision. It is essential to consider factors such as soil type, depth requirements, and the nature of the project to ensure you choose equipment that meets your operational demands effectively.

When evaluating drilling equipment options, it's important to assess the technical specifications and capabilities of each tool. Different projects may require specialized equipment, such as rotary drills for hard rock, augers for softer soils, or advanced technologies for precision drilling. By analyzing the unique features of each type of drilling equipment, you can determine which tools will maximize efficiency and minimize operational risks. Ultimately, the right choice of drilling equipment will lead to more productive outcomes and greater overall project success.

When selecting drilling equipment for a project, it is crucial to first

identify the specific requirements of the task at hand. Understanding the

geological conditions, the depth and diameter of the borehole, and the

type of material to be drilled through can significantly influence the

choice of equipment. For instance, projects involving hard rock

might necessitate a more robust drilling rig compared to those working

with softer soil. Additionally, considering

the environmental impact and regulatory

requirements of your project will help in narrowing down suitable options.

Tips: Always conduct a

thorough site assessment before making any equipment choice. Engaging with

geological experts can provide valuable insights into the subsurface

conditions that will dictate the necessary drilling parameters.

Moreover, evaluating the scale and timeline of your project is essential.

Larger projects may require advanced equipment capable of sustained

operations under demanding conditions, while smaller jobs might be effectively

accomplished with basic tools. Keep in mind the

maintenance and operational costs associated with the equipment, as these

factors can affect the overall budget of your project.

Tips: Create a checklist of

project specifications that includes depth, drilling speed,

and material types. Use this checklist as a reference when consulting

with equipment suppliers to ensure you choose the right gear for your needs.

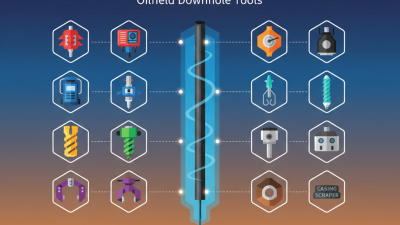

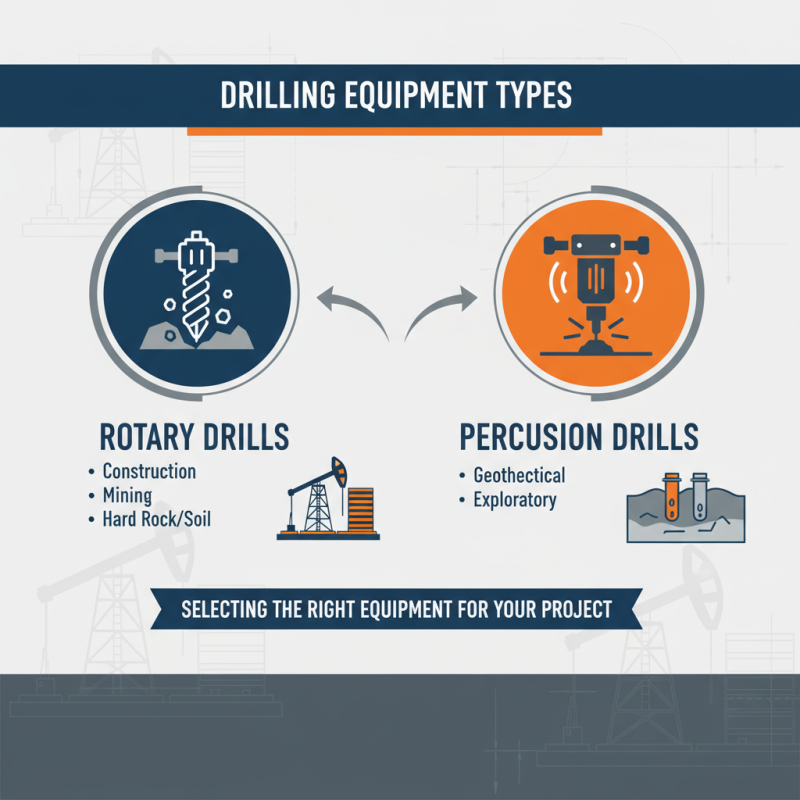

When selecting drilling equipment for your project, it's essential to understand the various types available and their specific applications. The most common type of drilling equipment includes rotary drills, which are used for a wide range of projects, from construction to mining. These drills utilize a rotating bit to cut through the material, making them suitable for hard rock or soil. Additionally, there are percussion drills that strike the ground repeatedly to break up tough surfaces, making them ideal for geotechnical work and exploratory drilling.

Another important category is the auger drill, which is widely used for soil sampling and post-hole digging. Augers come in various sizes and configurations, allowing for versatility depending on the requirements of your project. Similarly, cable tool drilling is a traditional method still used in certain contexts, particularly in water well drilling, where the heavy tools are repeatedly dropped to create a borehole. Each type of drilling equipment is designed to handle specific conditions and material types, so understanding these distinctions is vital to ensure you choose the right tool for maximum efficiency and effectiveness in your project.

When selecting drilling equipment for your project, evaluating performance specifications and capabilities is crucial. Different projects demand different types of drilling tools, such as rotary drilling rigs or impact hammers, each with unique operational characteristics. According to a recent industry report by the International Association of Drilling Contractors, understanding parameters like penetration rate, torque, and weight on bit can significantly influence the overall efficiency of a drilling operation. For instance, a rotary drill with an optimal weight on bit can improve penetration rates by up to 30%, drastically reducing project timelines and costs.

Additionally, considering the capabilities of the equipment in relation to the geological conditions is essential. The Society of Petroleum Engineers emphasizes the importance of selecting equipment that not only meets the depth requirements but can also handle varying formations, such as hard rock or sedimentary layers. For instance, certain drills are specifically designed with advanced bit technologies that enhance their performance in challenging geological conditions, which can lead to a 25% increase in operational efficiency. Therefore, aligning the drilling equipment’s specifications with project-specific needs will optimize productivity and ensure successful project completion.

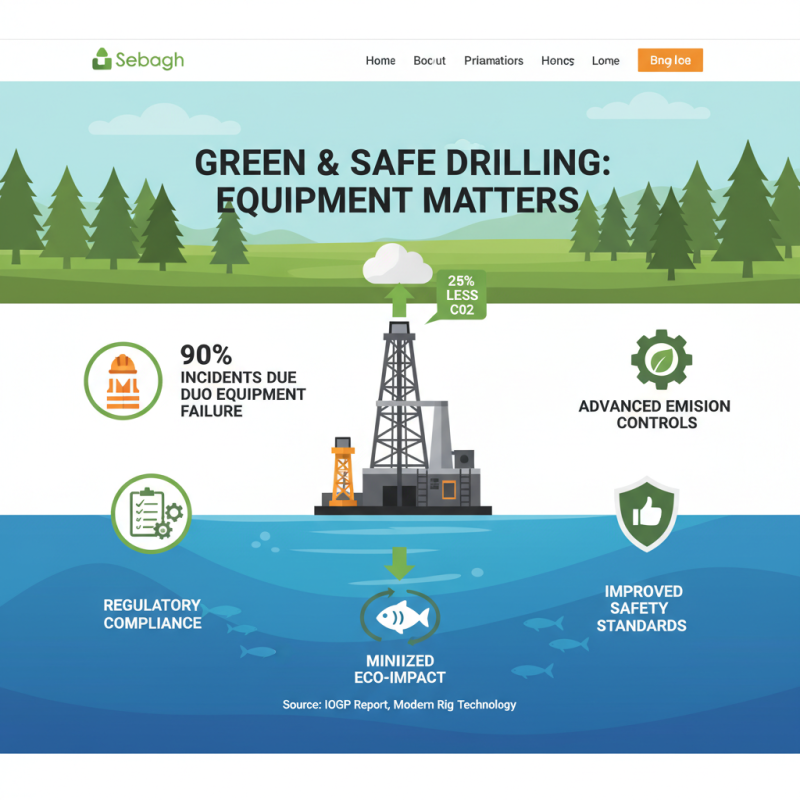

When selecting drilling equipment for any project, it is essential to prioritize environmental and safety factors to ensure compliance with regulatory standards and to minimize impact on surrounding ecosystems. According to a report by the International Association of Oil & Gas Producers (IOGP), nearly 90% of drilling-related incidents are attributed to equipment failures or improper use. Therefore, understanding the environmental footprint of the chosen equipment is paramount. For example, modern rigs equipped with advanced emission control technologies can reduce greenhouse gas emissions by up to 25%, significantly contributing to more sustainable drilling operations.

Safety considerations also play a critical role in the equipment choice process. The Occupational Safety and Health Administration (OSHA) reports that approximately 9,000 drilling injuries occur annually in the United States, often due to inadequate equipment safety features. Selecting drilling gear that incorporates robust safety mechanisms, such as automatic shut-off systems and enhanced visibility technologies, is essential for protecting workers and reducing accident risks. Furthermore, adhering to environmental regulations, such as the Clean Water Act, necessitates the use of equipment designed to prevent leaks and spills, thereby safeguarding local water sources from contamination. By evaluating equipment based on these criteria, project managers can ensure they are making informed decisions that align with safety and environmental best practices.

When selecting drilling equipment for a project, budgeting and cost analysis play a crucial role in ensuring you stay within financial constraints while meeting project demands. Begin by assessing the full scope of your project to understand the specific drilling needs, including depth, material types, and duration. This initial assessment will guide your budgeting process by allowing you to identify potential costs associated with different equipment options.

Tip: Always allocate a contingency budget of around 10-15% to cover unexpected expenses that may arise during the project. This will provide you with flexibility to accommodate unforeseen challenges without compromising the quality of your work.

Next, research the total cost of ownership for the equipment you’re considering, which includes not only the initial purchase or rental price but also maintenance and operational costs. Different models may have varying efficiencies, and these affect long-term financial implications. Analyzing these factors will help you make informed decisions that align with your budget while ensuring that you select the right equipment for the task.

Tip: Create a comparison chart for different equipment options, including all cost components, to facilitate easy evaluation. This visual representation helps clarify which options provide the best value for your project’s specific needs.