-

Home

-

About TKL

-

Factory Tour

-

Products

-

Blog

-

Contact Us

CONTACT

Leave Your Message

CONTACT

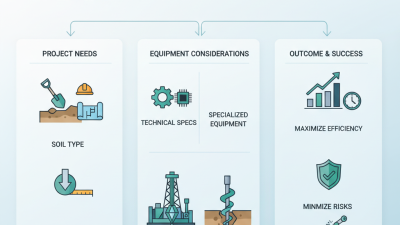

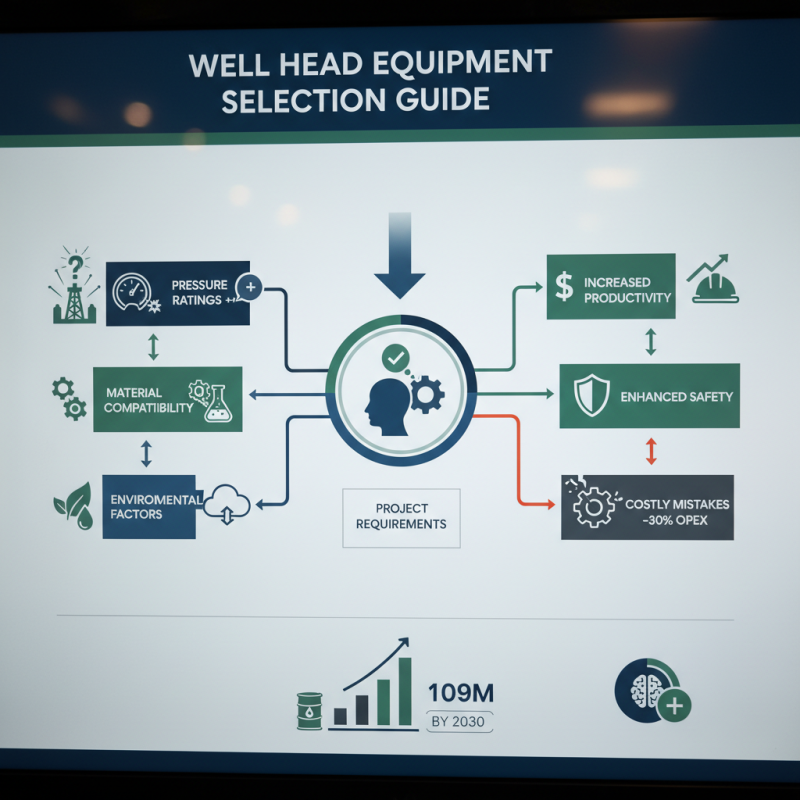

Choosing the right Well Head Equipment is crucial for the success of any oil and gas project. The global demand for oil and gas is projected to reach 109 million barrels per day by 2030, leading to increased focus on efficient extraction methods. In this context, selecting the appropriate equipment can significantly impact both productivity and safety.

Expert John Stevens, a leading figure in the Well Head Equipment industry, once stated, “The right equipment can make or break a project.” His insights underline the importance of understanding specific project requirements and the equipment involved. Factors such as pressure ratings, material compatibility, and environmental considerations must be evaluated carefully.

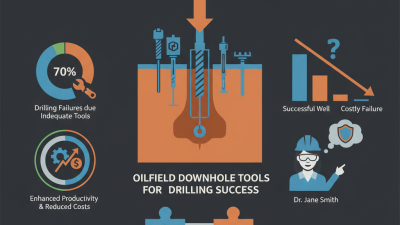

However, many projects overlook these considerations, leading to costly mistakes. Industry reports indicate that improper equipment selection can increase operating costs by up to 30%. It's essential to reflect on the implications of these choices. Investing adequate time in this decision-making process is not merely advisable; it is essential for the success and longevity of operations.

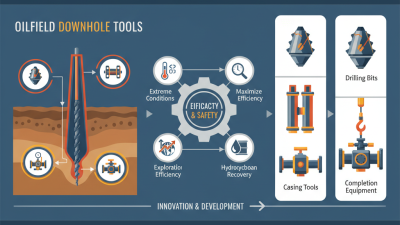

Well head equipment plays a crucial role in oil and gas projects. It serves as the primary interface between the well and the surface facilities. Choosing the right well head equipment is essential for operational efficiency and safety. According to a recent report by the International Energy Agency, improper installation or substandard equipment can lead to significant financial losses, estimated to reach up to 20% of total project costs.

Choosing equipment involves understanding the specific needs of your project. Factors like well depth, pressure, and fluid types all influence the decision. Oil and gas wells can experience high pressure, sometimes exceeding 20,000 psi. Selecting a well head that can withstand these conditions is critical. Neglecting this can lead to failures, potential leaks, and safety hazards.

Tip: Always consult with experts who can provide insights based on the latest data and technology trends. It's important to review industry standards and best practices.

Remember, while state-of-the-art technology is attractive, simpler designs may often be more effective. They can reduce complexity and the potential for failure. Analyze both new technologies and traditional equipment. Consider long-term maintenance and support aspects carefully. The choice should not be taken lightly, as it impacts both project success and environmental safety.

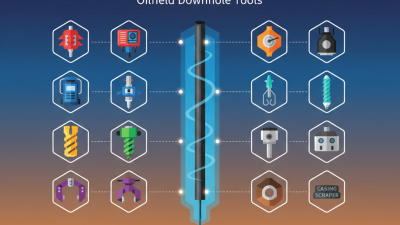

Selecting well head equipment is a crucial step in any drilling project. Different projects have unique requirements. It's vital to assess the specific conditions in which the equipment will operate. Factors such as depth, pressure, and temperature influence the type of equipment needed.

Another important consideration is the material of the well head. It should withstand harsh environments. Corrosion resistance can be a key factor in prolonging the life of the equipment. Moreover, compatibility with other components in the system cannot be overlooked. Ensuring everything fits together seamlessly reduces future complications.

Don't forget about the regulatory standards that apply. Complying with local regulations is mandatory. Sometimes, these requirements can be confusing. Regularly reviewing them ensures that your project remains compliant. The decision-making process may feel overwhelming, but taking time to evaluate these factors leads to better overall outcomes.

| Criteria | Description | Importance Level |

|---|---|---|

| Pressure Rating | The maximum pressure the equipment can handle. | High |

| Material Compatibility | Suitability of materials used in equipment with the well fluids. | High |

| Temperature Range | The operational temperature limits of the equipment. | Medium |

| Maintenance Requirements | Frequency and complexity of required maintenance tasks. | Medium |

| Installation Ease | How easily the equipment can be installed on site. | Low |

| Cost | Total financial investment needed. | High |

| Supplier Reputation | Track record and reliability of the supplier. | Medium |

| Compliance Standards | Adherence to relevant industry and safety standards. | High |

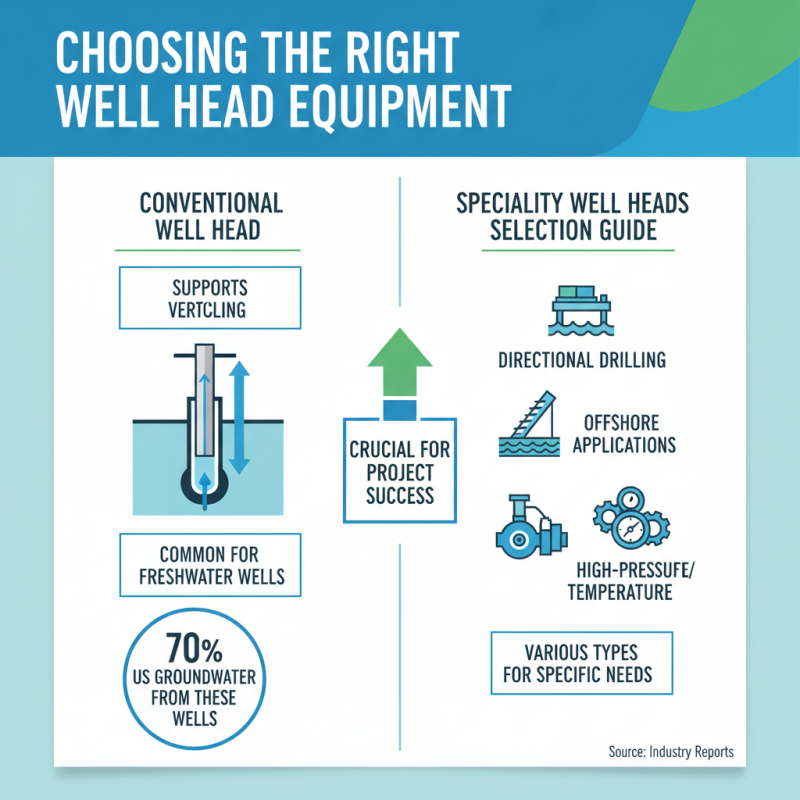

Choosing the right well head equipment is crucial for any project. The types of well head equipment vary widely, each designed for specific applications. For example, a conventional well head supports vertical drilling. It’s often employed in freshwater wells, where groundwater extraction is key. According to industry reports, over 70% of groundwater supply in the U.S. comes from such wells.

In contrast, subsea well heads are essential for offshore drilling. These are used in deeper water applications, where pressure and temperature are much higher. Studies indicate that subsea wells can yield 20% more production compared to traditional methods. However, they come with higher initial costs and require extensive expertise. This raises questions about cost-effectiveness in marginal fields and the ongoing maintenance challenges.

Moreover, the choice of equipment impacts safety and environmental considerations. Inadequate selection may lead to leaks or failures, costing companies dearly. Ineffective sealing arrangements can cause catastrophic results, jeopardizing not just finances but also lives. Thus, evaluating the specific needs and risks associated with each type of well head equipment is imperative for project success.

When evaluating the performance and reliability of well head equipment, several factors come into play. Robust materials and manufacturing processes ensure longevity. Corrosion resistance and weathering are crucial for outdoor installations. Equipment should withstand varying pressures and temperatures encountered in the field.

Tips: Always check for certifications and compliance with industry standards. This guarantees that the equipment meets safety and quality expectations. Test results from previous projects provide insight into reliability and functionality.

Often overlooked, maintenance plays a significant role. Scheduled inspections help detect wear and tear early. Regular servicing can extend the life of the well head. Reflect on past experiences to avoid mistakes. Prioritize flexibility too, as needs may change over time.

Choosing the right equipment is not just about upfront costs. Invest in reliable options for long-term savings. Don't skimp on quality; it pays off in operational efficiency. Focus on the equipment’s history and reviews from other projects.

Selecting the right well head equipment involves significant cost considerations. Budgeting for these systems requires careful analysis of both upfront costs and long-term expenses. While the initial investment can be daunting, understanding the operational costs helps clarify overall budget needs. Equipment maintenance and replacement should not be overlooked. They can heavily impact your finances.

Consider fluctuating prices for equipment based on market conditions. Conduct thorough research to estimate these costs accurately. Don’t forget to account for installation fees. They can add up quickly and affect your budget more than anticipated. Unexpected expenses may arise during the project. Leaving room in your budget for contingencies is wise, as it ensures you won’t be caught off guard.

Engaging with experts and evaluating various options helps streamline your selection process. However, remember that the cheapest option isn't always the best. A balance between price and quality is crucial. Reflecting on past projects can guide your decisions, highlighting what worked and what didn’t. Each project is unique, and learning from previous experiences will enhance your budgeting process.