-

Home

-

About TKL

-

Factory Tour

-

Products

-

Blog

-

Contact Us

CONTACT

Leave Your Message

CONTACT

Choosing the right drilling equipment is critical for project success. The global drilling equipment market is projected to reach $10 billion by 2026, according to Industry Research Firm. This growth reflects the increasing demand for efficient and high-quality drilling solutions across various industries. Selecting the best equipment can significantly impact project timelines and budgets.

Expert John Smith, a leading consultant in the drilling sector, emphasizes, "Investing in the right drilling equipment transforms the efficiency of any operation." His insight highlights the importance of matching equipment to project requirements. Factors such as terrain, project scale, and technology advancements should guide your choice.

Yet, the process is not always straightforward. Many contractors face challenges in assessing their actual needs versus available options. Mistakes in selection can lead to losses, delays, and safety issues. It's essential to thoroughly evaluate each choice and ensure it aligns with both project demands and industry standards. Understanding the complexities of drilling equipment will ultimately lead to more informed decisions.

When choosing drilling equipment, understanding your project requirements is crucial. Each project has unique demands. The soil type, depth, and purpose of drilling all impact your choice. For instance, soft soil may require lighter equipment, while rocky terrain needs more robust machines. Cost is another factor. A tight budget may restrict options, leading to compromises.

Consider the size of your project. Small residential drilling jobs will not need the same equipment as large construction sites. If you underestimate the requirements, it could lead to equipment failures. Always assess your needs thoroughly. Don’t rush into decisions.

A short consultation with a professional can help clarify what’s necessary. Communicating your specific needs is essential. Mistakes can arise from vague requirements. You may end up with equipment that's either too advanced or insufficient for what you need. Reflecting on past projects can provide valuable insights, steering your choices in the right direction.

When selecting drilling equipment, understanding the types available is crucial. There are several options on the market. Rotary drills are commonly used. They excel in penetrating hard materials. These machines are ideal for large projects requiring deep holes.

Percussion drills are another choice. They use a hammering action to break through tough surfaces. This type works well in rocky terrains. For light tasks, handheld drills are popular. They're portable and user-friendly. Many users find comfort with their lightweight design.

Tips: Always assess the project needs before purchasing. Consider the soil type, depth, and project scale. Renting equipment can be a smart choice for short-term projects. It allows for experimentation without a big commitment. Be mindful of the maintenance costs as well. Unforeseen repairs can add up quickly. What feels like a small project today could grow rapidly. Evaluate wisely before making your final decision.

| Equipment Type | Description | Applications | Advantages |

|---|---|---|---|

| Rotary Drills | Utilizes a rotating drill bit to penetrate soil and rock. | Mining, oil exploration, water well drilling. | Efficient for deep drilling; suitable for various materials. |

| Auger Drills | Uses a helical screw to remove soil or rock. | Geotechnical surveys, foundation drilling. | Good for shallow applications; easy to operate. |

| Percussion Drills | Uses a hammering action to break rock. | Exploration drilling, hard rock mining. | Effective for hard materials; deep penetration. |

| Diamond Core Drills | Uses a diamond-tipped bit for high precision. | Geological core sampling, mineral exploration. | Provides high-quality core samples; versatile. |

| Handheld Drills | Small, portable drills for light-duty tasks. | Landscaping, small construction projects. | Highly portable; easy to use; cost-effective. |

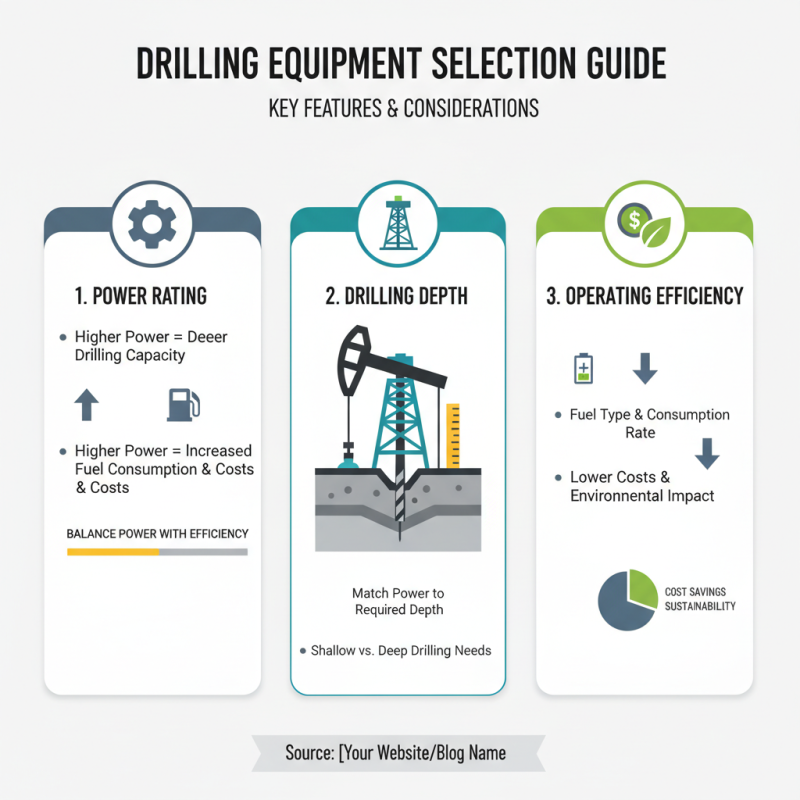

When selecting drilling equipment, understanding its key features is crucial. The power rating is one of the first aspects to evaluate. Higher power ratings typically allow for deeper drilling. However, they can also increase fuel consumption, leading to higher costs. Balance power with efficiency.

Another essential feature is portability. Lightweight equipment may be easier to transport, but heavier models often offer more stability and durability. Consider your project’s location and whether you can transport the equipment effortlessly. Mobility may save time but impacts your budget.

Tip: Look for equipment with adjustable settings. This feature can increase versatility across different projects. Consider noise levels too. Equipment that runs quietly can be a significant advantage in residential areas. Always check reviews for real-world performance.

Finally, evaluate the safety features. Drilling can be dangerous. Safety guards and automatic shut-off systems can protect operators. It’s important not to overlook these essential aspects. Balancing features with costs often leads to a suitable choice.

When selecting drilling equipment, evaluating manufacturer reputation is key. Trusted companies typically have a strong track record of performance. A recent industry report indicated that over 70% of projects succeed with equipment from well-reviewed manufacturers. Customer feedback plays a crucial role in this evaluation, as it provides real-world insights.

Look for reviews that detail long-term performance. Many customers share experiences regarding equipment durability and efficiency. Keep an eye out for any recurring issues mentioned in reviews. It's better to avoid equipment with consistent complaints about reliability.

Tips: Examine ratings across multiple platforms. Understand that no equipment is flawless. Some users may have had different experiences. A mix of positive and negative reviews often indicates a well-rounded perspective. Perhaps the equipment works great in some conditions but not in others. Recognizing this can save you time and money in the long run.

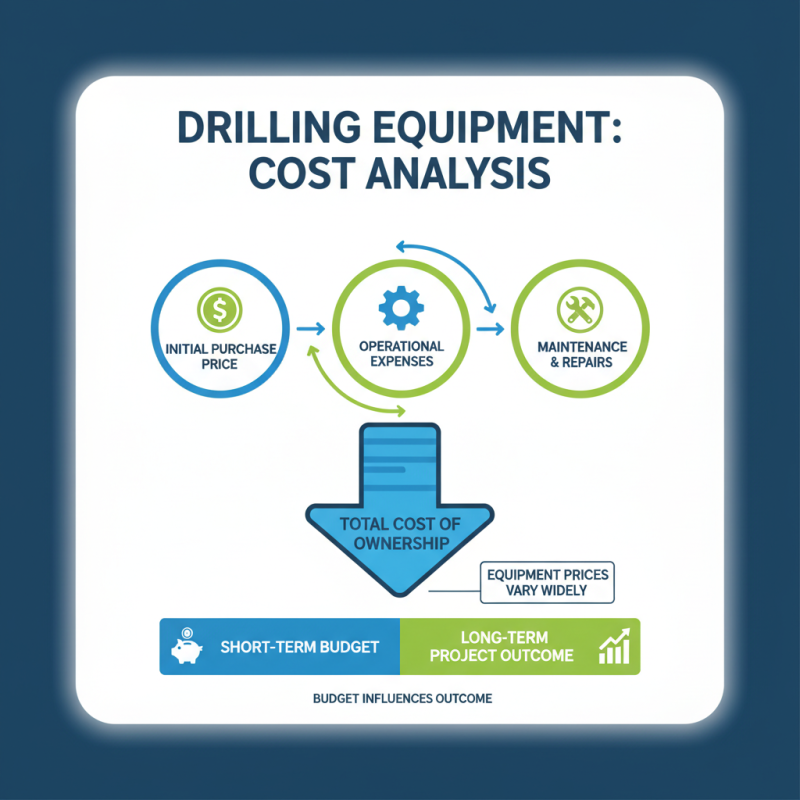

When selecting drilling equipment, cost analysis is essential. Budget considerations can greatly influence the overall project outcome. Equipment prices vary widely. It’s not just the initial cost that matters. Maintenance and operational expenses accumulate over time.

Estimating costs involves several factors. Research typical pricing for various equipment in your area. Don't forget to account for additional costs. Transportation, setup, and potential downtime can inflate your budget unexpectedly. Sometimes, a cheaper option may require more repairs, leading to higher long-term costs.

Reflecting on your budget is vital. Ensure you have a safety net for unforeseen expenses. Consider a contingency fund for unexpected repairs. Ask yourself: Are you overestimating some costs? Or, are you underestimating others? Careful evaluation can save both time and money in the long run. Prioritize quality, but stay within your means.