-

Home

-

About TKL

-

Factory Tour

-

Products

-

Blog

-

Contact Us

CONTACT

Leave Your Message

CONTACT

In the oil and gas industry, managing a Blowout Well effectively is critical for safety and efficiency. A blowout can cause serious damage if not handled properly. Operators must utilize the best techniques to minimize risks while maximizing production.

Selecting the right blowout prevention methods makes a difference. Each technique has its strengths and weaknesses. Some may work better in specific conditions. Learning from past incidents is essential. Mistakes happen; understanding them can guide improved practices.

Adopting innovative strategies can enhance blowout prevention. Pressure management, proper equipment, and trained personnel are key elements. There is always room for improvement in this challenging field. The goal is to find a balance between efficiency and safety, harnessing the full potential of Blowout Wells while reducing hazards.

Blowout well techniques are critical in the oil and gas industry. These methods help manage pressure and prevent uncontrolled releases. Inefficient practices can lead to safety hazards and financial losses. According to a 2022 industry report, improper handling of blowouts can cost companies millions in damages and lost productivity.

Effective blowout techniques include proper pressure monitoring and control systems. Utilizing advanced sensors can reduce response time. Data show that companies implementing real-time monitoring see a 30% decrease in incidents. However, many organizations still rely on outdated methods. This creates risk in high-pressure environments.

Training personnel is equally important. Skilled workers are essential to operate complex equipment. A recent survey indicated that 40% of incidents were due to human error. Regular training can mitigate this risk. Engineers should also review past incident reports. Learning from mistakes can enhance safety protocols significantly. Adopting these fundamentals can lead to safer and more efficient operations.

Evaluating the efficiency and performance of blowout wells involves several key metrics. One primary metric is the rate of production. This indicates how quickly resources are extracted. A high production rate suggests effective operational processes. However, this might not always reflect overall efficiency. Sometimes, rapid extraction can lead to depletion of resources over time.

Another crucial metric is the cost per unit. This includes all expenses incurred during operations. Monitoring these costs helps identify areas for improvement. If expenses are consistently high, teams should reflect on the techniques used. Are there ways to streamline processes? A focus on reducing waste can improve overall performance.

Safety measures also play a significant role in evaluation. Incidents during operations can halt production and incur extra costs. Tracking safety records provides insight into the reliability of techniques employed. An uptick in incidents could indicate a need for reevaluation of current practices. Each of these metrics contributes to a comprehensive understanding of blowout well efficiency. Emphasizing these aspects can foster continuous improvement in operations over time.

Effective fluid management is crucial during blowout operations. When a blowout occurs, maintaining control over fluid reinjection and handling can minimize risks.

Proper fluid circulation helps in balancing pressure and stabilizing the well. Technicians must ensure that the mud weight is appropriate to prevent further issues.

Monitoring fluid levels requires consistent attention. Operators should regularly check for changes in volume that could indicate leaks. Obscure fluctuations might hint at larger problems.

It’s essential to adapt to these changes quickly. Behavior patterns of the fluids can signal how the operation is progressing.

Some operational procedures may seem efficient but can be flawed. For instance, not all types of fluids work well in every scenario.

Choosing the wrong fluid can lead to complications. Personnel should be prepared to adjust their strategies.

This adaptability makes a significant difference in outcomes. Flexibility in approach is key to successful blowout management.

Blowout prevention is critical in the oil and gas industry. Innovative technologies play a vital role in enhancing safety and efficiency. Recent reports indicate that up to 80% of blowouts occur due to human error. This highlights the need for advanced systems that support operators in crucial decision-making.

One effective approach is the implementation of real-time data analytics. By utilizing sensors, operators can monitor pressure and temperature changes continuously. This technology can reduce response time by 50%. Automated systems can predict hazardous conditions, enabling timely interventions. However, reliance on technology can be a double-edged sword. If the system fails or provides inaccurate data, it could lead to severe consequences.

Another area of development is the integration of artificial intelligence. AI algorithms can analyze historical data, identifying patterns that human operators might overlook. A study showed that AI systems could improve blowout risk assessment by up to 30%. Still, the challenge remains in ensuring that human oversight is not diminished. Balancing automation with necessary human input is essential for effective blowout prevention strategies.

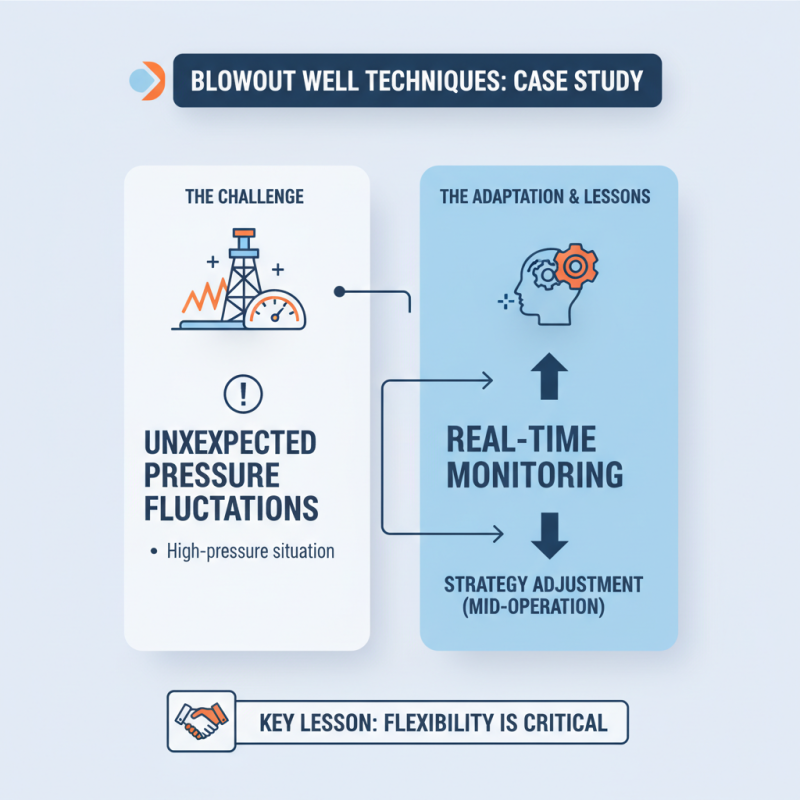

In the world of blowout well techniques, successful case studies often reveal valuable lessons. One notable example involved a team that faced unexpected pressure fluctuations. They adapted quickly, using real-time monitoring tools. This allowed them to adjust their strategy mid-operation, showcasing the importance of flexibility in high-pressure situations.

Tips: Embrace real-time data. It can significantly improve response times. Always be prepared to pivot your approach based on field conditions.

Another case study highlighted a well where equipment failure led to costly delays. The team analyzed the failure and found that regular maintenance could have prevented it. This experience taught them to prioritize proactive measures over reactive responses.

Tips: Implement a thorough maintenance schedule. Address potential issues before they escalate. Regular training sessions can help your team handle emergencies better.

These stories emphasize the need for continuous improvement. Learning from both successes and failures is crucial for refining blowout well techniques. Embracing a culture of learning can elevate operations significantly.