-

Home

-

About TKL

-

Factory Tour

-

Products

-

Blog

-

Contact Us

CONTACT

Leave Your Message

CONTACT

In the ever-evolving landscape of construction and manufacturing, the efficiency and precision of tools play a crucial role in project success. One such innovative tool that has gained significant attention is the Pipe Swaging Machine. As noted by industry expert John Smith, “The Pipe Swaging Machine is a game-changer for anyone looking to enhance the quality and speed of their piping projects.” This highlights the transformative impact that this machinery can have on various applications, from plumbing to structural piping.

The Pipe Swaging Machine offers a multitude of benefits, making it an invaluable asset to professionals across different sectors. Its ability to reshape and join pipes with minimal effort not only streamlines the production process but also enhances the integrity of the connections. With advancements in technology, these machines are designed to deliver consistent results while reducing the risk of errors, ultimately leading to cost-effectiveness and improved project timelines.

In this discussion, we will explore the top benefits of using a Pipe Swaging Machine for your projects, shedding light on how integrating this tool can elevate your operational efficiency and result in superior outcomes. Whether you are a seasoned contractor or a novice in the industry, understanding the advantages of this machinery can significantly impact your work.

Pipe swaging machines offer numerous advantages in the field of metalworking, making them an essential tool for various projects. One of the primary benefits is the ability to create precise and uniform shapes in pipes, which is crucial for ensuring fittings and components maintain integrity throughout their use. This precision helps reduce the risk of leaks and failures, enhancing the overall quality of the final product. Additionally, the efficiency of swaging machines allows for quicker processing times, enabling manufacturers to meet demanding deadlines without compromising on quality.

Another significant advantage of using pipe swaging machines is their versatility. These machines can work with a variety of materials, including different types of metals and alloys, making them suitable for diverse applications in industries such as automotive, construction, and plumbing. The capability to easily switch between tasks means that metalworking professionals can adapt to changing project requirements without needing multiple pieces of equipment. This flexibility not only saves time and space but also reduces operational costs, contributing to a more streamlined workflow in metal fabrication processes.

The use of a pipe swaging machine significantly enhances efficiency in pipe fabrication processes, a critical aspect for industries requiring precision and speed. These machines streamline the shaping and resizing of pipes without the need for extensive manual intervention. By allowing operators to quickly adjust the dimensions of pipes, a swaging machine reduces the time spent on manual fittings and adjustments, leading to faster project turnarounds.

Additionally, the consistency achieved through swaging technology cannot be understated. Unlike traditional methods that may result in variations due to human error, a pipe swaging machine delivers uniform results with every operation. This precision not only improves the quality of the final product but also minimizes material waste, making processes both economical and environmentally friendly.

As industries increasingly demand both agility and sustainability, the integration of swaging machines represents a pivotal advancement in manufacturing and construction projects.

Utilizing pipe swaging technology can significantly enhance the cost-effectiveness of various projects, particularly in industries where precision and efficiency are paramount. By streamlining the way pipes are reshaped and joined, swaging machines reduce the amount of material wasted during fabrication. This translates not only to lower raw material costs but also to decreased labor expenses, as the time required for traditional cutting and welding processes is minimized. The efficiency of swaging allows for quicker project turnaround times, which can lead to increased productivity and faster returns on investment.

Moreover, the investment in pipe swaging technology proves economically viable in the long run. As these machines are capable of producing consistent and high-quality connections, the need for rework and repairs diminishes, further enhancing overall cost savings. Additionally, the durability and strength of swaged connections contribute to the longevity of the infrastructure, reducing future maintenance costs. By incorporating pipe swaging into project workflows, businesses can achieve a more sustainable and financially sound approach, ensuring that budgets are adhered to while maintaining high standards of performance.

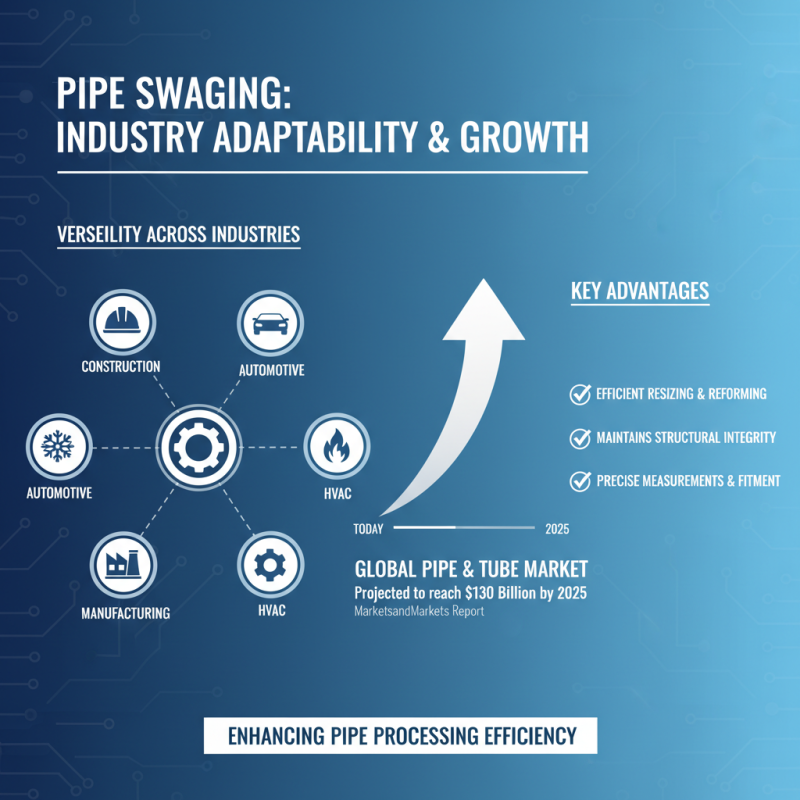

The versatility of pipe swaging machines is a significant advantage that caters to a broad spectrum of industries including construction, automotive, HVAC, and manufacturing. According to a report by MarketsandMarkets, the global pipe and tube market is projected to reach $130 billion by 2025, indicating a rising demand for efficient pipe processing tools. Swaging machines enhance this process by allowing for the resizing and reforming of pipes and tubes without losing structural integrity, which is critical for applications that require precise measurements and fitment.

In the construction industry, swaging machines are particularly valuable for creating customized sections of piping that materialize specific project requirements. This method minimizes the need for additional fittings, which not only reduces material costs by an estimated 20% but also streamlines installation procedures, leading to quicker project completion times. Similarly, in the automotive sector, where lightweight yet durable materials are essential for enhancing vehicle performance and fuel efficiency, swaged pipes provide the necessary adaptability and strength to meet these demands. As a result, industries that leverage swaging technology can achieve greater efficiency and productivity, ultimately contributing to their bottom line. The flexibility of these machines ensures they remain essential tools across multiple applications, driving innovation and cost savings in various fields.

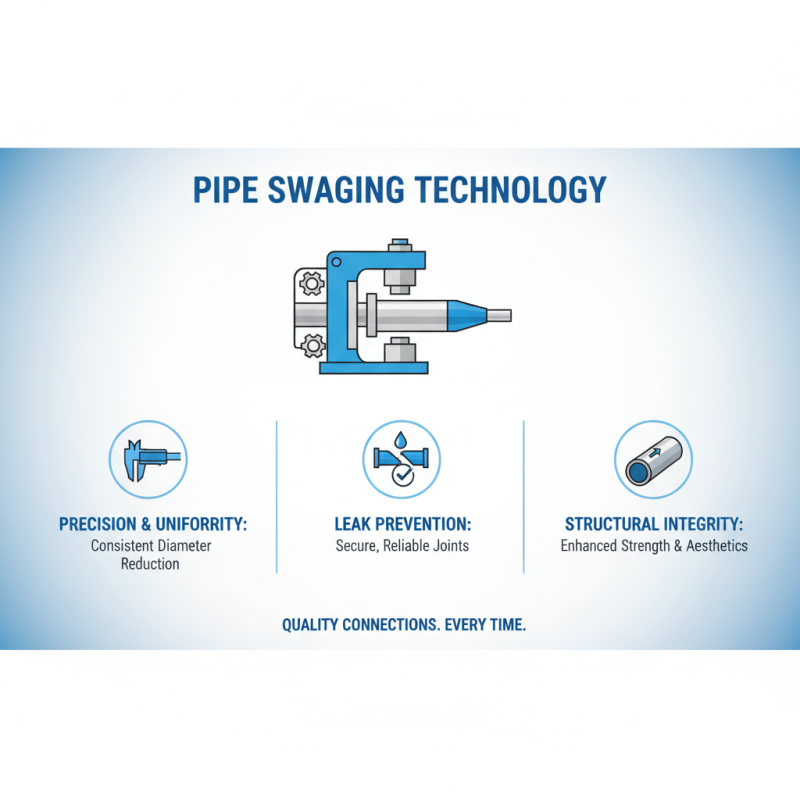

Using a pipe swaging machine significantly enhances the precision and quality of swaged connections. This technology allows for consistent diameter reduction, ensuring that every joint created is uniform and meets stringent specifications. The machine operates by applying controlled force to the pipe, which reshapes it seamlessly without compromising its structural integrity. This not only boosts the aesthetic appeal of the connections but also reduces the risk of leaks, which is crucial in applications where reliability is paramount.

Tips for maximizing precision with a pipe swaging machine include ensuring that the material to be swaged is free from contaminants and imperfections. Additionally, it is essential to regularly calibrate the machine to maintain its accuracy over time. Understanding the specific requirements of the project, such as the desired angle and fit of the connection, will further enhance the quality of the outcome. Proper training on the equipment can also lead to more efficient operations and better results, ensuring that all connections are made to the highest standards.